Unlocking Efficiency: A Comprehensive Guide to ERP Systems for Manufacturing

.

.

Welcome, fellow manufacturers! In today’s fast-paced, competitive landscape, staying ahead of the curve is paramount. This means embracing technological advancements that streamline operations, optimize resource allocation, and empower your business to thrive. Enter the world of Enterprise Resource Planning (ERP) systems, a powerful suite of software designed to integrate and manage all aspects of your manufacturing enterprise.

Imagine a single, unified platform that seamlessly connects your production, inventory, sales, finance, and human resources departments. This is the promise of an ERP system, offering a holistic view of your business, enabling informed decision-making, and driving efficiency across the board.

But the journey to ERP implementation can seem daunting. Questions about cost, complexity, and compatibility may arise. Fear not, for this comprehensive guide is your roadmap to understanding ERP systems, their benefits, and how they can revolutionize your manufacturing operations. We’ll delve into the intricacies of ERP systems, explore the advantages and disadvantages, and equip you with the knowledge to make informed decisions for your business.

From Chaos to Control: The Power of ERP Systems

.

.

Manufacturing businesses face a unique set of challenges, from managing complex supply chains and intricate production processes to ensuring quality control and meeting demanding customer expectations. Traditional, siloed systems often struggle to keep pace, leading to inefficiencies, delays, and increased costs.

This is where ERP systems step in as a game-changer. By centralizing data and processes, ERP systems break down departmental silos, fostering collaboration and transparency. Imagine a scenario where your sales team can access real-time inventory data, preventing overselling and ensuring timely order fulfillment. Or envision a scenario where your production team can track material usage and identify potential bottlenecks, optimizing production schedules and minimizing waste.

The Advantages of Embracing ERP: A Transformation in Your Manufacturing Landscape

The benefits of implementing an ERP system extend far beyond mere data integration. These systems empower your manufacturing business to:

1. Streamline Operations: A Symphony of Efficiency

Imagine a manufacturing process where every step, from raw material procurement to finished goods delivery, is meticulously orchestrated. This is the reality that ERP systems bring to life. By automating repetitive tasks, eliminating manual data entry, and streamlining workflows, ERP systems free up your team to focus on strategic initiatives.

.

.

2. Boost Productivity: A Catalyst for Growth

Imagine a scenario where your production team is empowered with real-time insights into material availability, machine performance, and production schedules. This is the power of ERP systems, enabling them to optimize production runs, minimize downtime, and maximize output.

3. Enhance Collaboration: A Unified Front

Imagine a scenario where your sales, production, and finance teams are all working from the same playbook, with access to the same real-time data. This is the power of ERP systems, breaking down departmental silos and fostering seamless collaboration.

4. Improve Decision-Making: Data-Driven Insights

.

.

Imagine a scenario where your leadership team has access to a comprehensive dashboard, providing real-time insights into key performance indicators (KPIs) such as production efficiency, inventory levels, and sales performance. This is the power of ERP systems, enabling informed decision-making based on accurate, up-to-date data.

5. Reduce Costs: Optimizing Resource Allocation

Imagine a scenario where your business can optimize inventory levels, minimize waste, and streamline production processes. This is the power of ERP systems, helping you reduce operational costs and maximize profitability.

6. Enhance Customer Satisfaction: Meeting Expectations with Precision

Imagine a scenario where your customers receive accurate order confirmations, timely delivery updates, and exceptional customer service. This is the power of ERP systems, enabling you to meet customer expectations and build lasting relationships.

.

.

7. Gain Competitive Advantage: A Strategic Edge

Imagine a scenario where your business is equipped with the agility and responsiveness to adapt to changing market conditions, capitalize on new opportunities, and outmaneuver competitors. This is the power of ERP systems, providing you with the tools to stay ahead of the curve.

Exploring the Landscape: Types of ERP Systems for Manufacturing

While the core functionalities of ERP systems remain consistent, different types cater to specific needs and industry verticals.

1. Cloud-Based ERP Systems: Flexibility and Scalability

.

.

Imagine a scenario where your ERP system is accessible from anywhere, anytime, on any device. This is the power of cloud-based ERP systems, offering unparalleled flexibility and scalability.

2. On-Premise ERP Systems: Control and Customization

Imagine a scenario where your ERP system is hosted on your own servers, providing you with complete control over data security and customization. This is the power of on-premise ERP systems, offering a high level of customization and security.

3. Industry-Specific ERP Systems: Tailored Solutions for Manufacturing

Imagine a scenario where your ERP system is specifically designed to meet the unique requirements of your manufacturing industry, such as automotive, aerospace, or pharmaceuticals. This is the power of industry-specific ERP systems, offering tailored solutions for specific challenges.

Navigating the Implementation Process: A Roadmap to Success

Implementing an ERP system is a significant undertaking, requiring careful planning and execution. Here’s a roadmap to guide you through the process:

1. Define Your Business Needs: A Clear Vision

Before embarking on the ERP journey, it’s crucial to define your business needs and objectives. What are your pain points? What are your goals for improving efficiency, productivity, and customer satisfaction?

2. Research and Select the Right ERP System: A Strategic Choice

Once you’ve identified your needs, it’s time to research and select the ERP system that aligns with your business requirements. Consider factors such as functionality, scalability, cost, and vendor support.

3. Prepare for Implementation: A Smooth Transition

Implementation is a complex process that requires careful planning and coordination. Ensure that you have the necessary resources, expertise, and support to ensure a successful transition.

4. Train Your Team: Embracing the New System

Proper training is essential for maximizing the benefits of your ERP system. Ensure that your team is fully trained on the system’s functionalities, workflows, and best practices.

5. Monitor and Optimize: Continuous Improvement

Once your ERP system is live, it’s important to monitor its performance and identify areas for improvement. Regular reviews and optimization efforts will ensure that your system continues to meet your evolving business needs.

The Advantages and Disadvantages of ERP Systems: A Balanced Perspective

While ERP systems offer numerous benefits, it’s important to acknowledge their potential drawbacks.

Advantages:

- Improved Efficiency: Streamlined workflows, automated processes, and reduced manual tasks lead to significant efficiency gains.

- Enhanced Productivity: Real-time data insights enable optimized production schedules, minimized downtime, and maximized output.

- Enhanced Collaboration: Breaking down departmental silos fosters seamless communication and collaboration across your organization.

- Improved Decision-Making: Comprehensive data insights enable informed decision-making based on accurate and up-to-date information.

- Reduced Costs: Optimized inventory management, minimized waste, and streamlined processes contribute to significant cost savings.

- Enhanced Customer Satisfaction: Improved order accuracy, timely delivery updates, and exceptional customer service lead to increased customer satisfaction.

- Gain Competitive Advantage: Agility, responsiveness, and data-driven insights empower your business to outmaneuver competitors and seize opportunities.

Disadvantages:

- High Implementation Costs: Implementing an ERP system can be a significant investment, requiring upfront costs for software licenses, hardware, and consulting services.

- Complexity and Learning Curve: ERP systems are complex and require significant training and adaptation for your team.

- Potential for Disruptions: Implementing a new system can disrupt existing workflows and require adjustments to established processes.

- Data Security Concerns: Storing sensitive data within an ERP system raises concerns about data security and privacy.

- Customization Challenges: Tailoring an ERP system to meet your specific business needs can be challenging and require specialized expertise.

- Vendor Dependence: Reliance on a specific ERP vendor can limit your flexibility and create dependence on their support and updates.

Essential Considerations for Choosing the Right ERP System

Choosing the right ERP system is a critical decision that can have a profound impact on your business. Here are some essential considerations:

1. Functionality: Meeting Your Specific Needs

Consider the specific functionalities that are essential for your manufacturing operations, such as production planning, inventory management, quality control, and financial reporting.

2. Scalability: Accommodating Growth

Ensure that the ERP system you choose can scale with your business as it grows. Consider factors such as user capacity, data storage, and processing power.

3. Cost: Balancing Value and Budget

ERP systems can range in price from a few thousand dollars to millions of dollars. Consider your budget and the value proposition of different systems.

4. Vendor Support: A Reliable Partner

Choose a vendor with a strong track record of providing reliable support and updates. Consider factors such as response times, technical expertise, and customer service.

5. Integration: Seamless Connectivity

Ensure that the ERP system you choose can integrate seamlessly with your existing systems, such as CRM, accounting software, and warehouse management systems.

6. Customization: Tailoring the Solution

Consider the level of customization that is available with different ERP systems. Some systems offer greater flexibility to tailor the solution to your specific business needs.

7. Security: Protecting Your Data

Data security is a paramount concern for any manufacturing business. Ensure that the ERP system you choose has robust security features to protect your sensitive data.

8. User-Friendliness: A Seamless Experience

Choose an ERP system with a user-friendly interface that is intuitive and easy for your team to learn and use.

9. Industry-Specific Solutions: Tailored for Manufacturing

Consider ERP systems specifically designed for the manufacturing industry, offering tailored functionalities and insights.

10. Implementation Support: A Smooth Transition

Ensure that the vendor provides comprehensive implementation support, including training, documentation, and ongoing assistance.

FAQs: Addressing Common Questions About ERP Systems

1. What are the benefits of using an ERP system in manufacturing?

ERP systems offer numerous benefits for manufacturing businesses, including improved efficiency, enhanced productivity, enhanced collaboration, improved decision-making, reduced costs, enhanced customer satisfaction, and a competitive advantage.

2. How much does it cost to implement an ERP system?

The cost of implementing an ERP system can vary significantly depending on the size and complexity of your business, the chosen software, and the level of customization required.

3. How long does it take to implement an ERP system?

The implementation timeline can vary depending on the complexity of the system, the size of your business, and the level of customization required. Implementation can take anywhere from a few months to several years.

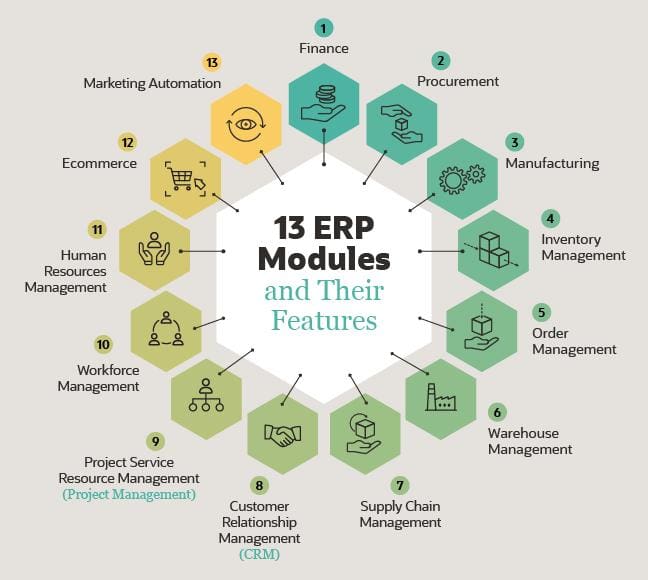

4. What are the key features of an ERP system for manufacturing?

Key features of an ERP system for manufacturing include production planning, inventory management, quality control, financial reporting, supply chain management, customer relationship management, and human resources management.

5. What are the challenges of implementing an ERP system?

Challenges of implementing an ERP system include high implementation costs, complexity and learning curve, potential for disruptions, data security concerns, customization challenges, and vendor dependence.

6. How can I choose the right ERP system for my business?

To choose the right ERP system, consider factors such as functionality, scalability, cost, vendor support, integration, customization, security, user-friendliness, industry-specific solutions, and implementation support.

7. What are some examples of popular ERP systems for manufacturing?

Popular ERP systems for manufacturing include SAP, Oracle, Infor, Epicor, and Microsoft Dynamics.

8. How can I ensure a successful ERP implementation?

To ensure a successful ERP implementation, carefully plan the process, define your business needs, select the right system, prepare for implementation, train your team, and monitor and optimize the system after go-live.

9. What are the best practices for managing an ERP system?

Best practices for managing an ERP system include regular system maintenance, data backups, user training, security updates, and ongoing monitoring and optimization.

10. What are the future trends in ERP systems for manufacturing?

Future trends in ERP systems for manufacturing include cloud-based solutions, artificial intelligence (AI) and machine learning (ML), Internet of Things (IoT) integration, and blockchain technology.

11. How can ERP systems help manufacturers improve sustainability?

ERP systems can help manufacturers improve sustainability by tracking and managing energy consumption, reducing waste, optimizing material usage, and monitoring environmental compliance.

12. What are the benefits of using an ERP system for small and medium-sized businesses (SMBs)?

ERP systems can provide significant benefits for SMBs, including improved efficiency, reduced costs, enhanced customer satisfaction, and a competitive advantage.

13. How can I learn more about ERP systems for manufacturing?

You can learn more about ERP systems for manufacturing by attending industry events, reading industry publications, and consulting with ERP vendors and consultants.

Conclusion: Embracing the Future of Manufacturing with ERP Systems

In a world where efficiency, agility, and data-driven insights are paramount, ERP systems have emerged as a transformative force for manufacturing businesses. By centralizing data, streamlining processes, and empowering informed decision-making, ERP systems unlock new levels of operational excellence, fostering growth, profitability, and customer satisfaction.

As you embark on your ERP journey, remember that choosing the right system is just the first step. Careful planning, thorough implementation, and ongoing optimization are essential for maximizing the benefits of your ERP investment.

Embrace the power of ERP systems to transform your manufacturing operations, empower your team, and propel your business to new heights of success.

Disclaimer: This article is intended for informational purposes only and should not be construed as professional advice. The information provided is based on current knowledge and best practices, but may not be applicable to all situations. It is essential to consult with qualified professionals for specific guidance and recommendations.

.

.