Navigating the Manufacturing Maze: Unlocking Efficiency with an ERP System

.

.

Welcome, fellow manufacturers! In today’s fiercely competitive landscape, navigating the intricate complexities of manufacturing operations is a constant struggle. From managing intricate supply chains to streamlining production processes, every aspect demands meticulous attention and unwavering efficiency. But what if there was a solution to conquer these challenges and propel your manufacturing business towards unprecedented success? Enter the realm of Enterprise Resource Planning (ERP) systems, a revolutionary technology designed to empower manufacturers with the tools they need to thrive.

Imagine a single platform that consolidates all your critical business functions, from finance and inventory to production and sales. This is the promise of an ERP system, a comprehensive solution that streamlines your entire manufacturing ecosystem, fostering seamless communication, data transparency, and real-time insights. But the journey to implementing an ERP system can be daunting, riddled with questions about its benefits, complexities, and potential pitfalls. Fear not, for this comprehensive guide will illuminate the path, providing a deep dive into the world of manufacturing ERP systems, unraveling their intricacies, and unveiling their transformative power.

We will explore the diverse array of ERP systems available, delving into their unique functionalities and strengths. We will dissect the advantages and disadvantages, empowering you to make informed decisions tailored to your specific needs. We will navigate the implementation process, providing practical tips and strategies for a seamless transition. And finally, we will address the common concerns and questions surrounding ERP systems, offering clear and concise answers to guide you through every step of the journey.

Let’s embark on this enlightening exploration, unraveling the mysteries of manufacturing ERP systems and discovering how they can revolutionize your operations, boost your productivity, and propel your business to new heights of success.

The Power of ERP: Streamlining Manufacturing Operations

At its core, an ERP system acts as the central nervous system of your manufacturing business, connecting all departments and processes into a cohesive and efficient unit. Imagine a symphony orchestra, where each musician plays their part flawlessly, guided by the conductor’s baton. An ERP system acts as the conductor, orchestrating the complex interplay of departments, ensuring smooth flow of information, and driving optimal performance.

But the benefits of an ERP system extend far beyond mere coordination. It empowers manufacturers with a wealth of valuable data, providing real-time insights into inventory levels, production schedules, customer orders, and financial performance. This data-driven approach enables manufacturers to make informed decisions, optimize resource allocation, and identify potential bottlenecks before they disrupt production.

Unveiling the Diverse Landscape of Manufacturing ERP Systems

The world of ERP systems is vast and diverse, offering a wide range of solutions tailored to specific industry needs. Some systems are designed for large-scale enterprises with complex operations, while others cater to small and medium-sized businesses (SMBs) seeking streamlined solutions.

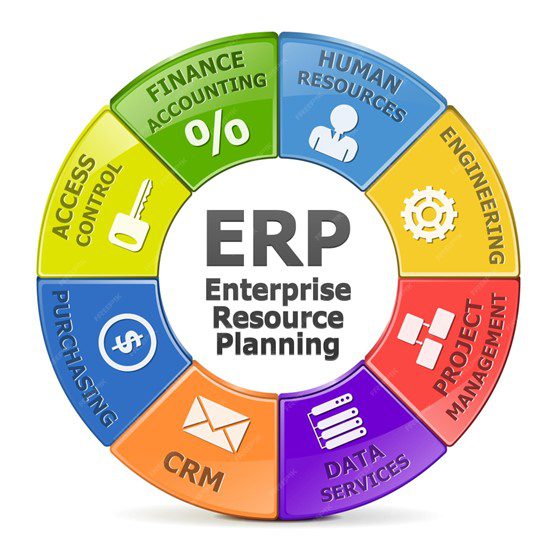

Understanding the Key Components of a Manufacturing ERP System

.

.

To effectively harness the power of an ERP system, it’s crucial to understand its core components and how they work together to drive efficiency and profitability.

1. Production Planning and Scheduling

At the heart of any manufacturing operation lies the ability to plan and schedule production effectively. An ERP system provides the tools to optimize production processes, ensuring timely delivery of finished goods while minimizing waste and maximizing resource utilization.

2. Inventory Management

Maintaining optimal inventory levels is a delicate balancing act. Too much inventory ties up valuable capital, while too little can lead to production delays and lost sales. An ERP system streamlines inventory management, providing real-time visibility into stock levels, automating purchase orders, and optimizing inventory turnover.

.

.

3. Quality Control

Maintaining consistent product quality is paramount in any manufacturing business. An ERP system enables manufacturers to track quality metrics, identify potential defects, and implement corrective actions to ensure product excellence.

4. Supply Chain Management

In today’s globalized marketplace, managing a complex supply chain is essential for success. An ERP system provides tools to track materials, monitor supplier performance, and optimize logistics, ensuring a seamless flow of goods from raw materials to finished products.

5. Finance and Accounting

.

.

Managing finances is a critical aspect of any business, and manufacturers are no exception. An ERP system integrates financial data, automates accounting tasks, and provides real-time insights into financial performance, empowering manufacturers to make informed decisions and ensure financial stability.

6. Customer Relationship Management (CRM)

Building strong customer relationships is essential for long-term success. An ERP system can integrate with CRM software, providing a comprehensive view of customer interactions, enabling manufacturers to personalize communication, enhance customer service, and foster loyalty.

7. Human Resources (HR)

Managing a workforce effectively is crucial for any manufacturing business. An ERP system can integrate with HR software, streamlining payroll, benefits administration, and employee training, freeing up valuable time for HR professionals to focus on strategic initiatives.

.

.

The Advantages of Implementing a Manufacturing ERP System

The benefits of implementing an ERP system are numerous and far-reaching, impacting every aspect of your manufacturing business.

1. Enhanced Efficiency and Productivity

By streamlining processes, eliminating manual tasks, and providing real-time insights, an ERP system empowers manufacturers to operate more efficiently and productively.

2. Improved Inventory Management

An ERP system provides real-time visibility into inventory levels, enabling manufacturers to optimize stock levels, reduce waste, and minimize the risk of stockouts.

3. Enhanced Quality Control

An ERP system allows manufacturers to track quality metrics, identify potential defects, and implement corrective actions, ensuring consistent product quality.

4. Streamlined Supply Chain Management

An ERP system provides tools to track materials, monitor supplier performance, and optimize logistics, ensuring a seamless flow of goods from raw materials to finished products.

5. Improved Financial Management

An ERP system integrates financial data, automates accounting tasks, and provides real-time insights into financial performance, empowering manufacturers to make informed decisions and ensure financial stability.

6. Enhanced Customer Satisfaction

By improving communication, streamlining order fulfillment, and providing personalized service, an ERP system can enhance customer satisfaction and build stronger relationships.

7. Increased Profitability

By optimizing operations, reducing costs, and enhancing efficiency, an ERP system can contribute to increased profitability for manufacturing businesses.

The Disadvantages of Implementing a Manufacturing ERP System

While the advantages of an ERP system are undeniable, there are also potential drawbacks to consider.

1. High Implementation Costs

Implementing an ERP system can be a significant investment, involving hardware, software, and professional services.

2. Complex Implementation Process

Implementing an ERP system requires careful planning, extensive customization, and thorough testing, which can be a time-consuming and complex process.

3. Potential for Resistance from Employees

Employees may resist the adoption of a new system, fearing job displacement or changes to their work processes.

4. Data Security Risks

An ERP system stores sensitive data, making it vulnerable to security breaches. It’s crucial to implement robust security measures to protect data integrity.

5. Limited Customization Options

Some ERP systems may offer limited customization options, making it challenging to adapt the system to specific business needs.

6. Ongoing Maintenance and Support Costs

After implementation, an ERP system requires ongoing maintenance, updates, and support, which can add to the overall cost.

Navigating the Implementation Process: A Step-by-Step Guide

Implementing an ERP system is a complex undertaking, requiring careful planning and execution to ensure a smooth transition and maximize benefits.

1. Define Your Business Requirements

Before selecting an ERP system, it’s crucial to define your specific business requirements, including your industry, size, and operational processes.

2. Research and Evaluate ERP Systems

Once you have defined your requirements, research and evaluate different ERP systems available, considering factors such as functionality, cost, and vendor reputation.

3. Select an ERP System

Based on your evaluation, select an ERP system that best meets your needs and budget.

4. Plan and Implement the System

Develop a comprehensive implementation plan, including timelines, resources, and training requirements.

5. Train Your Employees

Provide comprehensive training to your employees on how to use the new system, ensuring they are comfortable and proficient.

6. Test and Go Live

Thoroughly test the system before going live, ensuring all processes work as expected.

7. Monitor and Optimize

After go-live, monitor the system’s performance and make adjustments as needed to optimize its effectiveness.

Addressing Common Concerns and Questions

As you embark on your ERP journey, you may have questions and concerns. Here are some common ones, along with their answers:

1. What are the key factors to consider when selecting an ERP system?

When selecting an ERP system, consider your specific business needs, industry, size, budget, and the vendor’s reputation and support services.

2. How can I ensure a smooth implementation process?

Ensure a smooth implementation by defining clear requirements, developing a comprehensive plan, training your employees, and testing the system thoroughly before go-live.

3. What are the potential risks associated with implementing an ERP system?

Potential risks include high implementation costs, complex implementation processes, resistance from employees, data security risks, limited customization options, and ongoing maintenance costs.

4. How can I mitigate the risks of implementing an ERP system?

Mitigate risks by selecting a reputable vendor, carefully planning the implementation process, providing comprehensive training, and implementing robust security measures.

5. What are the best practices for managing an ERP system?

Best practices include regular maintenance, updates, and backups, as well as ongoing monitoring and optimization to ensure the system remains effective.

6. How can I measure the return on investment (ROI) of an ERP system?

Measure ROI by tracking key performance indicators (KPIs) such as increased efficiency, reduced costs, improved inventory management, and enhanced customer satisfaction.

7. What are the future trends in ERP systems?

Future trends include cloud-based ERP systems, mobile-friendly interfaces, and integration with artificial intelligence (AI) and machine learning (ML) technologies.

8. How can I stay updated on the latest ERP developments?

Stay updated by attending industry conferences, reading industry publications, and networking with other ERP users.

9. What are the best resources for learning more about ERP systems?

Resources include industry websites, vendor websites, online forums, and ERP consulting firms.

10. What are the common mistakes to avoid when implementing an ERP system?

Common mistakes include failing to define clear requirements, neglecting to plan adequately, underestimating the complexity of implementation, and not providing sufficient training.

11. How can I ensure that my ERP system is scalable and flexible?

Select a system that is scalable and flexible, allowing you to adapt to changing business needs and growth.

12. What are the key considerations for data security when implementing an ERP system?

Key considerations include data encryption, access controls, regular security audits, and employee training on data security best practices.

13. How can I get the most out of my ERP system investment?

Maximize your investment by fully utilizing the system’s functionalities, providing ongoing training to employees, and continuously monitoring and optimizing its performance.

The Power of Transformation: Embracing the Future of Manufacturing

As you stand at the precipice of this transformative journey, consider the potential of an ERP system to revolutionize your manufacturing operations. It’s not just about streamlining processes and boosting efficiency, it’s about unlocking a new era of innovation, agility, and growth.

Embrace the power of data-driven decision-making, empower your workforce with the tools they need to thrive, and navigate the complexities of today’s manufacturing landscape with confidence. An ERP system is not just a technology, it’s a catalyst for change, a beacon of progress, and a gateway to a future where your manufacturing business reaches its full potential.

Call to Action: Embrace the Future of Manufacturing

Don’t let the complexities of manufacturing operations hold you back. Take the first step towards a future of efficiency, innovation, and success. Explore the world of ERP systems, identify the solution that aligns with your unique needs, and embark on a journey that will transform your business from within.

Remember, the power to shape your future lies within your grasp. Embrace the possibilities, unlock the potential of your manufacturing business, and let the journey begin!

Disclaimer: This article provides general information about manufacturing ERP systems and should not be considered as professional advice. It’s essential to consult with industry experts and conduct thorough research before making any decisions about implementing an ERP system. The information provided in this article is for informational purposes only and does not constitute a recommendation or endorsement of any specific ERP system or vendor. It’s crucial to evaluate your specific business needs and choose a system that aligns with your unique requirements.

.

.