Navigating the Complexities of Process Manufacturing: How ERP Systems Can Be Your Guiding Light

.

.

Welcome, fellow process manufacturers! In today’s dynamic and competitive landscape, navigating the intricate world of process manufacturing can feel like traversing a labyrinth. From managing complex production lines to ensuring consistent quality and optimizing resource allocation, the challenges are numerous and multifaceted. But fear not, for there exists a beacon of hope – a powerful tool that can illuminate your path and streamline your operations: Process Manufacturing ERP.

Unveiling the Power of Process Manufacturing ERP

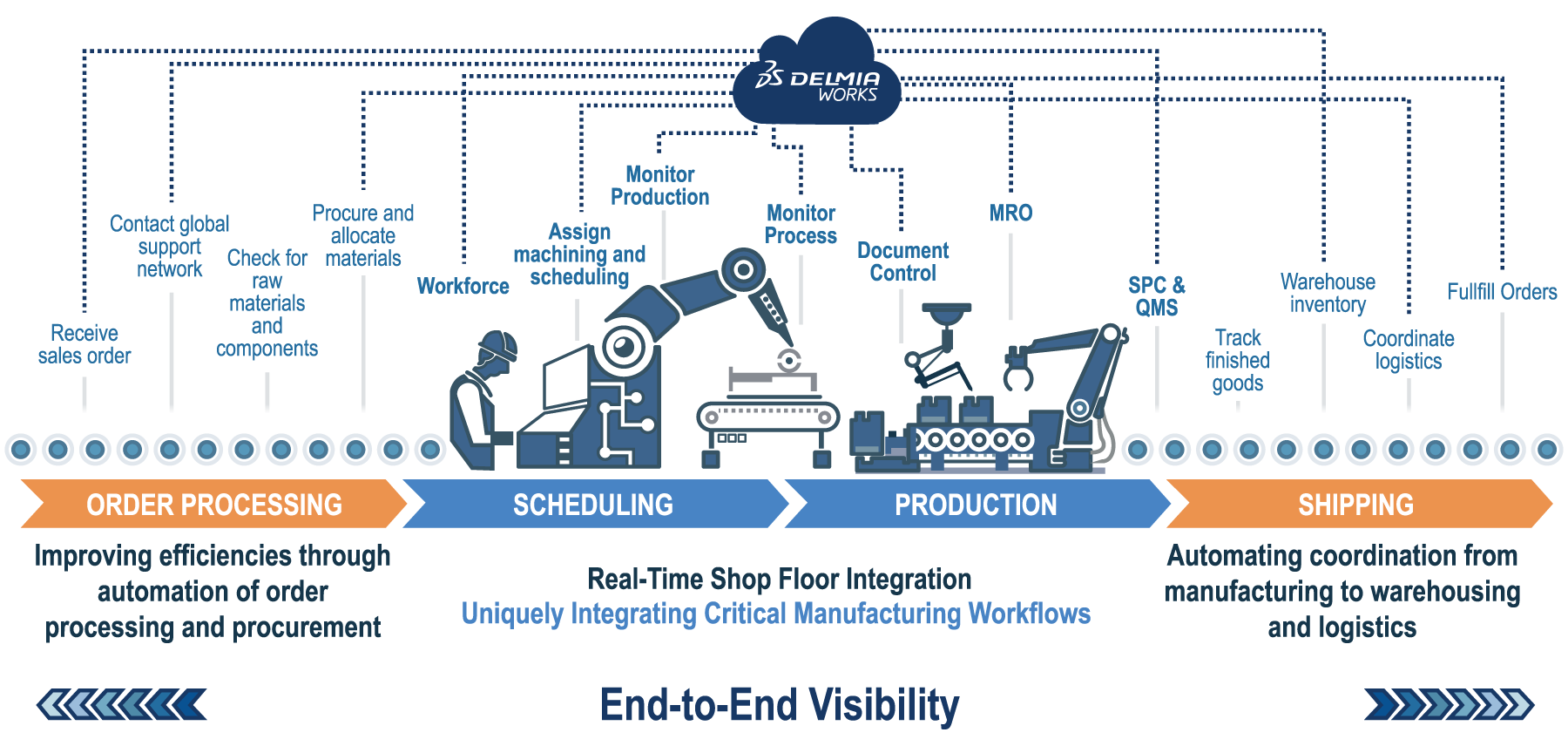

Imagine a system that seamlessly integrates all facets of your business, from raw material procurement to finished product distribution. This is the promise of process manufacturing ERP, a comprehensive software solution specifically designed to address the unique demands of process-oriented industries. By centralizing data, automating workflows, and providing real-time insights, ERP systems empower you to gain unparalleled control over your operations, optimize resource utilization, and elevate your overall efficiency.

The Essence of Process Manufacturing ERP

.

.

At its core, process manufacturing ERP is a sophisticated software system that encompasses various modules tailored to address the specific requirements of process-oriented industries. These modules typically include:

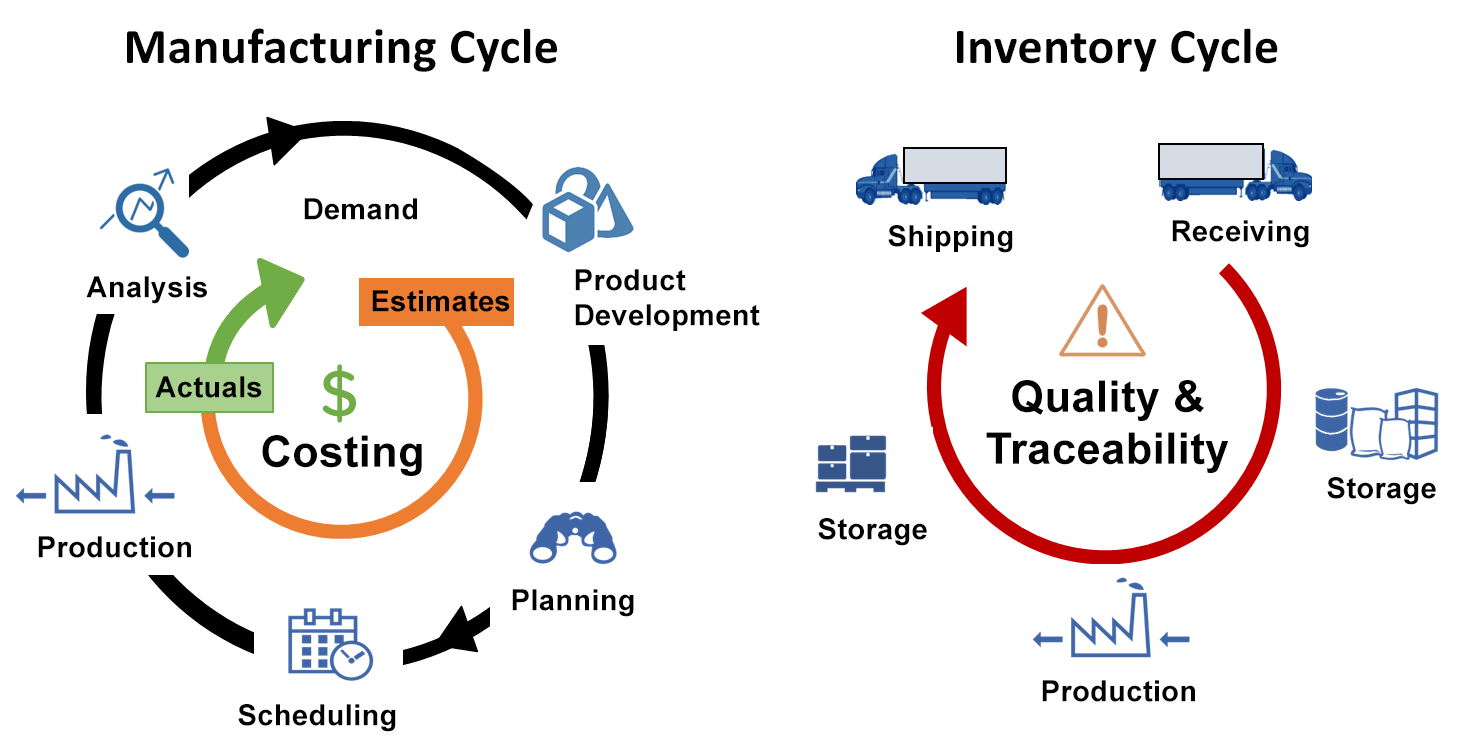

- Production Planning: This module enables you to meticulously plan your production schedules, taking into account factors such as raw material availability, production capacity, and customer demand.

- Inventory Management: Maintain a comprehensive inventory of raw materials, work-in-progress, and finished goods, ensuring optimal stock levels and minimizing waste.

- Quality Control: Implement robust quality control measures throughout your production process, ensuring adherence to strict standards and minimizing product defects.

- Financial Management: Gain complete visibility into your financial performance, track costs, manage budgets, and generate insightful financial reports.

- Supply Chain Management: Optimize your supply chain, from sourcing raw materials to delivering finished products, ensuring seamless flow and timely delivery.

- Customer Relationship Management (CRM): Build strong relationships with your customers, manage their orders, track their satisfaction, and foster loyalty.

.

.

The Benefits of Embracing Process Manufacturing ERP

Implementing a process manufacturing ERP system can unlock a plethora of benefits, transforming your operations and propelling your business forward. Here are some key advantages:

.

.

- Enhanced Efficiency: Streamline your production processes, reduce manual tasks, and optimize resource allocation, leading to significant efficiency gains.

- Improved Visibility: Gain real-time visibility into your entire operation, from raw material inventory to production progress and finished goods distribution.

- Reduced Costs: Minimize waste, optimize inventory levels, and streamline processes, resulting in substantial cost savings.

- Enhanced Quality: Implement robust quality control measures, track product quality throughout the production process, and ensure consistent product quality.

- Increased Agility: Adapt quickly to changing market conditions, customer demands, and regulatory requirements, ensuring your business remains competitive.

- Better Decision Making: Access real-time data and insightful analytics, empowering you to make informed decisions that drive business growth.

.

.

The Challenges of Implementing Process Manufacturing ERP

While the benefits of process manufacturing ERP are undeniable, implementing such a system can present its own set of challenges:

.

.

- High Initial Investment: Implementing an ERP system requires a significant upfront investment, including software licenses, hardware upgrades, and implementation costs.

- Complex Implementation: ERP implementation requires careful planning, skilled resources, and extensive training, which can be time-consuming and resource-intensive.

- Data Migration: Migrating existing data from legacy systems to the new ERP platform can be a complex and challenging process.

- Change Management: Adopting a new ERP system requires significant change management efforts to ensure user adoption and minimize resistance.

- Customization Requirements: Process manufacturing industries often have unique requirements that may necessitate extensive customization of the ERP system, adding to the implementation complexity.

Navigating the Implementation Process

Successfully implementing a process manufacturing ERP system requires a strategic approach and careful planning:

- Define Your Business Requirements: Clearly define your specific business needs and objectives to ensure the chosen ERP system meets your requirements.

- Select the Right ERP Solution: Carefully evaluate different ERP vendors and solutions, considering factors such as functionality, scalability, cost, and vendor support.

- Develop a Comprehensive Implementation Plan: Create a detailed implementation plan outlining timelines, resources, and key milestones to ensure a smooth transition.

- Provide Adequate Training: Invest in comprehensive training programs for users to ensure they are comfortable and proficient in using the new system.

- Ensure Effective Change Management: Implement strategies to manage change effectively, address user concerns, and encourage adoption of the new system.

Essential Features of Process Manufacturing ERP

To effectively address the unique demands of process manufacturing, ERP systems must offer specific features and functionalities:

- Batch Tracking and Traceability: Track and trace individual batches of products throughout the production process, ensuring product safety and regulatory compliance.

- Formula Management: Manage and control product formulas, ensuring consistency and accuracy in production processes.

- Process Control: Monitor and control critical process parameters, ensuring optimal production efficiency and product quality.

- Yield Management: Track and optimize production yields, minimizing waste and maximizing resource utilization.

- Quality Management: Implement robust quality control measures, track product quality, and ensure compliance with industry standards.

- Regulatory Compliance: Ensure compliance with relevant industry regulations and standards, including food safety, environmental protection, and data security.

The Future of Process Manufacturing ERP

The future of process manufacturing ERP is bright, with advancements in technology driving innovation and enhancing capabilities:

- Cloud-Based ERP: Cloud-based ERP solutions offer enhanced scalability, flexibility, and affordability, making them an attractive option for process manufacturers.

- Artificial Intelligence (AI): AI-powered features are transforming ERP systems, enabling predictive analytics, automated decision making, and enhanced efficiency.

- Internet of Things (IoT): Connecting production equipment and systems through IoT enables real-time data collection, process optimization, and predictive maintenance.

- Blockchain Technology: Blockchain can enhance supply chain transparency, traceability, and security, improving product safety and consumer trust.

Case Studies: Real-World Success Stories

Numerous process manufacturers have successfully implemented ERP systems, reaping significant benefits and achieving transformative results:

- Example 1: A leading food and beverage manufacturer implemented an ERP system to streamline its production processes, improve inventory management, and enhance customer service. The result was a 20% reduction in production costs and a 15% increase in customer satisfaction.

- Example 2: A pharmaceutical company implemented an ERP system to ensure compliance with stringent regulatory requirements, improve product quality, and enhance traceability. The system enabled them to meet regulatory standards, reduce product recalls, and improve patient safety.

FAQs: Addressing Your Questions

1. What are the key considerations when choosing a process manufacturing ERP system?

When selecting a process manufacturing ERP system, consider factors such as functionality, scalability, cost, vendor support, and industry expertise. Ensure the system meets your specific business requirements and integrates seamlessly with your existing systems.

2. How can I ensure a successful ERP implementation?

Successful ERP implementation requires careful planning, skilled resources, and effective change management. Define your business requirements, select the right solution, develop a comprehensive implementation plan, provide adequate training, and manage change effectively.

3. What are the benefits of cloud-based process manufacturing ERP?

Cloud-based ERP solutions offer enhanced scalability, flexibility, and affordability, making them attractive for process manufacturers. They provide access to the latest technology, reduce IT infrastructure costs, and enable remote access.

4. How can AI enhance process manufacturing operations?

AI-powered features can optimize production processes, predict demand fluctuations, identify potential quality issues, and automate decision making, leading to improved efficiency and profitability.

5. What are the challenges of integrating IoT into process manufacturing?

Integrating IoT into process manufacturing requires careful planning, data security measures, and robust network infrastructure. It also necessitates skilled personnel to manage and analyze the vast amounts of data generated by connected devices.

6. How can blockchain technology improve supply chain transparency?

Blockchain can track products throughout the supply chain, providing a secure and tamper-proof record of origin, movement, and transactions. This enhances transparency, traceability, and consumer trust.

7. What are the key industry trends shaping the future of process manufacturing ERP?

Key trends include the rise of cloud-based ERP, increasing adoption of AI and IoT, and the growing importance of data analytics and predictive modeling.

8. How can I measure the ROI of my ERP investment?

Measure ROI by tracking key performance indicators (KPIs) such as production efficiency, inventory turnover, cost reduction, and customer satisfaction. Compare these metrics before and after ERP implementation to assess the impact on your business.

9. What are some common mistakes to avoid during ERP implementation?

Common mistakes include inadequate planning, insufficient user training, poor change management, and neglecting data migration. Avoid these pitfalls to ensure a smooth and successful implementation.

10. How can I ensure user adoption of my new ERP system?

Encourage user adoption through comprehensive training, effective communication, and ongoing support. Provide user-friendly interfaces, address concerns promptly, and demonstrate the benefits of using the new system.

11. What are the best practices for managing data security in process manufacturing ERP?

Implement robust data security measures, including access control, encryption, and regular backups. Ensure compliance with industry regulations and best practices to protect sensitive data.

12. How can I leverage ERP data to improve decision making?

Use ERP data to generate insightful reports and dashboards, identify trends, and make informed decisions regarding production planning, inventory management, and customer service.

13. What are the latest advancements in process manufacturing ERP?

Advancements include the integration of AI, IoT, and blockchain technologies, as well as the development of cloud-based ERP solutions and mobile applications.

Embracing the Future of Process Manufacturing

As you embark on your journey to optimize your process manufacturing operations, remember that process manufacturing ERP is not merely a software solution; it’s a strategic partner in your quest for success. By embracing its power, you can unlock new levels of efficiency, gain unparalleled visibility, and propel your business to new heights.

Call to Action

Don’t wait any longer to harness the transformative power of process manufacturing ERP. Take the first step today and explore the solutions available to you. Contact a reputable ERP vendor, schedule a consultation, and discover how ERP can revolutionize your operations and propel your business forward.

Disclaimer:

This article is intended to provide general information on process manufacturing ERP and should not be considered professional advice. Consult with qualified professionals for specific guidance and implementation strategies tailored to your unique business needs.

End Note:

The information provided in this article is intended for informational purposes only and does not constitute professional advice. The author is not responsible for any actions taken based on the information provided. Consult with qualified professionals for specific guidance and implementation strategies tailored to your unique business needs.

.

.