Navigating the Complexities of Manufacturing: Unlocking Efficiency with ERP Software

.

.

Welcome, fellow manufacturers! In today’s fast-paced and ever-evolving world, staying ahead of the curve is crucial for survival. As manufacturers, we face a unique set of challenges: managing intricate supply chains, optimizing production processes, and ensuring timely delivery of high-quality products while navigating fluctuating market demands. These challenges can feel overwhelming, leading to inefficiencies, lost productivity, and ultimately, a decline in profitability.

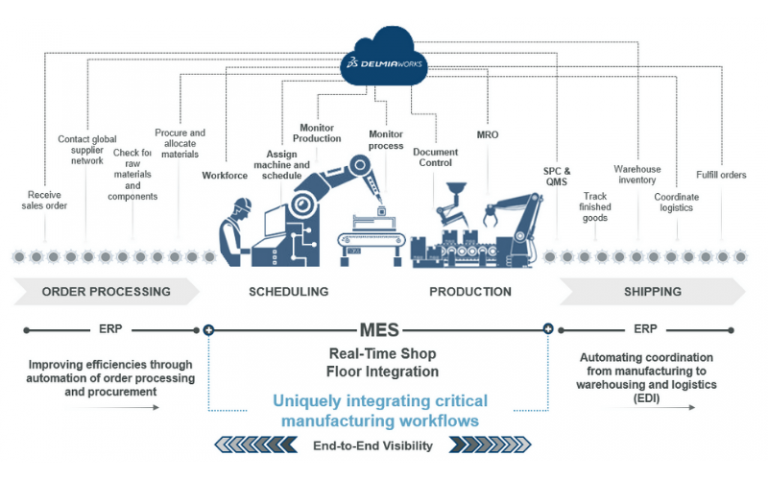

But there’s a solution that can revolutionize your manufacturing operations and propel your business towards success: Enterprise Resource Planning (ERP) software. Imagine a single, unified platform that seamlessly integrates all aspects of your business, from production planning and inventory management to customer relationship management and financial accounting. This is the promise of ERP software, and it’s transforming the manufacturing landscape.

The Need for a Unified System:

Traditionally, manufacturing businesses relied on disparate systems for each department, leading to data silos, communication breakdowns, and a lack of real-time visibility. Imagine trying to manage your inventory with one spreadsheet, track production schedules with another, and handle customer orders with a third. This fragmented approach creates chaos, hindering efficiency and hindering decision-making.

.

.

ERP: The Solution to Manufacturing Complexity:

ERP software emerges as a game-changer, offering a centralized platform that integrates all your essential business functions. This unified system streamlines workflows, eliminates data duplication, and provides real-time insights into every aspect of your operations. With ERP, you can:

- Gain Real-Time Visibility: Access up-to-the-minute information on inventory levels, production progress, customer orders, and financial performance, enabling informed decision-making.

- Optimize Production Processes: Streamline production schedules, manage resources effectively, and reduce downtime through automated processes and real-time data analysis.

- Improve Supply Chain Management: Track materials procurement, manage supplier relationships, and ensure timely delivery of raw materials, minimizing disruptions and delays.

- Enhance Customer Satisfaction: Process orders efficiently, manage customer interactions effectively, and provide timely and accurate information, fostering stronger customer relationships.

- Increase Profitability: Reduce operational costs, optimize resource utilization, and improve production efficiency, leading to higher profits and a stronger bottom line.

.

.

The Power of ERP: A Deeper Dive

Let’s delve deeper into the transformative power of ERP software and explore how it can address specific pain points faced by manufacturers.

.

.

1. Streamlining Production Planning and Scheduling:

A. Planning and Scheduling Made Easy:

ERP software revolutionizes production planning and scheduling by providing a centralized platform for managing all aspects of the process. Imagine a system that automatically generates production schedules based on customer demand, available resources, and production constraints. This eliminates manual scheduling errors, reduces lead times, and optimizes resource utilization.

B. Real-Time Visibility into Production Progress:

With ERP, you can track production progress in real-time, ensuring that your production lines are running smoothly and meeting deadlines. The system provides detailed insights into machine utilization, material consumption, and labor hours, enabling you to identify bottlenecks and make informed adjustments to optimize production efficiency.

.

.

C. Minimizing Downtime and Maximizing Efficiency:

ERP software empowers you to minimize downtime and maximize production efficiency. The system can automatically trigger maintenance alerts based on machine usage and historical data, preventing unexpected breakdowns and ensuring smooth production flow. By integrating with your existing equipment, ERP can provide real-time data on machine performance, enabling you to identify and address potential issues before they escalate.

D. Enhanced Collaboration and Communication:

ERP fosters seamless collaboration and communication between different departments involved in production planning and scheduling. The system provides a shared platform for sharing information, updates, and progress reports, ensuring everyone is on the same page and working towards common goals. This eliminates communication silos and reduces the risk of miscommunication, leading to smoother production processes and timely delivery of products.

E. Adapting to Changing Demands:

.

.

In today’s dynamic market, manufacturers need to be agile and responsive to changing customer demands. ERP software enables you to adapt production plans quickly and efficiently. The system can automatically adjust schedules based on changes in customer orders, material availability, or production constraints, ensuring you can meet evolving needs without compromising quality or efficiency.

2. Optimizing Inventory Management and Control:

A. Accurate Inventory Tracking:

ERP software provides real-time visibility into your inventory levels, ensuring you have the right materials at the right time. The system automatically tracks incoming and outgoing materials, monitors stock levels, and alerts you to potential shortages or surpluses, enabling you to optimize inventory management and minimize waste.

B. Minimizing Stockouts and Excess Inventory:

By providing accurate inventory data, ERP software helps you avoid stockouts and excess inventory. The system uses historical data and demand forecasting to predict future needs, enabling you to order materials efficiently and avoid unnecessary stockpiles. This reduces storage costs, minimizes waste, and ensures you have the materials you need when you need them.

C. Streamlined Procurement Processes:

ERP software streamlines your procurement processes, ensuring timely delivery of materials and reducing procurement costs. The system automates purchase orders, manages supplier relationships, and tracks delivery schedules, eliminating manual errors and improving efficiency. By integrating with your suppliers, ERP can facilitate real-time communication and collaboration, ensuring smooth and timely delivery of materials.

D. Improved Material Planning and Forecasting:

ERP software empowers you to plan and forecast material requirements more effectively. The system analyzes historical data, current demand, and production schedules to predict future material needs, enabling you to optimize material purchasing and minimize waste. By integrating with your production planning and scheduling systems, ERP can ensure that you have the right materials available at the right time, minimizing delays and disruptions.

E. Enhanced Quality Control:

ERP software can help you improve quality control by tracking material lots, managing product specifications, and monitoring production processes. The system can alert you to potential quality issues, enabling you to take corrective action before they escalate. By integrating with your quality management systems, ERP can provide a comprehensive overview of your quality performance, allowing you to identify areas for improvement and ensure consistent product quality.

3. Enhancing Supply Chain Management:

A. Real-Time Visibility into the Supply Chain:

ERP software provides real-time visibility into your entire supply chain, from raw material sourcing to finished product delivery. The system tracks material movement, monitors supplier performance, and provides insights into potential disruptions, enabling you to proactively manage risks and ensure timely delivery of products.

B. Streamlined Supplier Management:

ERP software streamlines your supplier management processes, improving communication, collaboration, and performance. The system automates purchase orders, tracks delivery schedules, and manages supplier performance metrics, enabling you to identify and work with reliable and efficient suppliers.

C. Improved Collaboration with Suppliers:

ERP software facilitates seamless collaboration with your suppliers. The system provides a shared platform for sharing information, updates, and progress reports, ensuring everyone is on the same page and working towards common goals. This eliminates communication silos and reduces the risk of miscommunication, leading to smoother supply chain operations and timely delivery of materials.

D. Reduced Lead Times and Improved Delivery Performance:

By optimizing supply chain processes, ERP software helps you reduce lead times and improve delivery performance. The system automates order processing, manages inventory levels, and tracks delivery schedules, ensuring timely and efficient delivery of products to your customers.

E. Enhanced Risk Management:

ERP software empowers you to proactively manage risks in your supply chain. The system monitors supplier performance, tracks material availability, and identifies potential disruptions, enabling you to take corrective action before they escalate. By integrating with your risk management systems, ERP can provide a comprehensive overview of your supply chain vulnerabilities, allowing you to develop mitigation strategies and minimize disruptions.

4. Streamlining Customer Relationship Management (CRM):

A. Centralized Customer Information:

ERP software provides a centralized platform for managing customer information, ensuring you have a complete and accurate view of your customer base. The system tracks customer interactions, purchase history, and preferences, enabling you to personalize your interactions and provide a better customer experience.

B. Improved Customer Service:

ERP software helps you improve customer service by providing real-time access to customer information, order history, and communication logs. This enables you to resolve customer issues quickly and efficiently, providing a more positive customer experience.

C. Enhanced Sales and Marketing Efforts:

ERP software can help you enhance your sales and marketing efforts by providing insights into customer behavior, purchase history, and preferences. This enables you to target your marketing campaigns more effectively and personalize your sales pitches, leading to increased conversion rates and customer loyalty.

D. Automated Order Processing:

ERP software automates order processing, reducing errors and improving efficiency. The system automatically generates invoices, tracks shipments, and manages customer accounts, freeing up your sales team to focus on building relationships and driving sales.

E. Improved Customer Satisfaction:

By providing excellent customer service, personalized interactions, and efficient order processing, ERP software helps you improve customer satisfaction and build stronger customer relationships. This leads to increased customer loyalty, repeat business, and positive word-of-mouth referrals.

5. Optimizing Financial Management:

A. Real-Time Financial Insights:

ERP software provides real-time insights into your financial performance, enabling you to make informed financial decisions. The system tracks revenue, expenses, cash flow, and profitability, providing a comprehensive overview of your financial health.

B. Improved Budgeting and Forecasting:

ERP software helps you improve budgeting and forecasting by providing historical financial data, real-time performance metrics, and demand forecasting tools. This enables you to create more accurate budgets, predict future financial performance, and make informed investment decisions.

C. Streamlined Accounting Processes:

ERP software automates accounting processes, reducing errors and improving efficiency. The system automatically generates invoices, tracks payments, and manages accounts payable and receivable, freeing up your accounting team to focus on more strategic tasks.

D. Enhanced Financial Reporting:

ERP software provides comprehensive financial reporting capabilities, enabling you to generate customized reports on your financial performance. The system can provide insights into key performance indicators, profitability by product line, and cash flow trends, enabling you to identify areas for improvement and make informed financial decisions.

E. Improved Compliance and Audit Readiness:

ERP software helps you improve compliance and audit readiness by providing a centralized platform for managing financial records. The system automates financial reporting, tracks transactions, and ensures compliance with relevant regulations, reducing the risk of audit findings and penalties.

6. Enhancing Business Intelligence and Analytics:

A. Data-Driven Decision Making:

ERP software provides a wealth of data that can be used to gain insights into your business operations and make informed decisions. The system tracks key performance indicators, identifies trends, and provides real-time visibility into your operations, enabling you to make data-driven decisions that optimize performance and drive growth.

B. Improved Reporting and Analysis:

ERP software provides comprehensive reporting and analysis capabilities, enabling you to generate customized reports on your business performance. The system can provide insights into production efficiency, inventory levels, customer behavior, and financial performance, enabling you to identify areas for improvement and make informed decisions.

C. Predictive Analytics and Forecasting:

ERP software can use historical data and machine learning algorithms to predict future trends and make more accurate forecasts. This enables you to anticipate demand fluctuations, optimize production schedules, and make informed investment decisions.

D. Identifying Opportunities for Improvement:

By analyzing data from your ERP system, you can identify opportunities for improvement in your business operations. The system can highlight areas where efficiency can be improved, costs can be reduced, or customer satisfaction can be enhanced.

E. Competitive Advantage:

By leveraging data analytics and business intelligence, you can gain a competitive advantage in your industry. The insights gained from your ERP system can help you identify market trends, develop new products and services, and optimize your operations for maximum efficiency and profitability.

7. Adapting to Industry 4.0 and the Future of Manufacturing:

A. Integration with Emerging Technologies:

ERP software is evolving to integrate with emerging technologies such as the Internet of Things (IoT), artificial intelligence (AI), and cloud computing. This enables you to leverage these technologies to improve your operations, enhance efficiency, and gain a competitive advantage.

B. Automation and Robotics:

ERP software can integrate with robotic systems and automation technologies, enabling you to automate repetitive tasks, improve production efficiency, and reduce labor costs.

C. Real-Time Data Analysis and Insights:

ERP software can leverage real-time data from sensors, machines, and other sources to provide real-time insights into your operations. This enables you to make informed decisions, optimize processes, and improve overall efficiency.

D. Predictive Maintenance and Asset Management:

ERP software can use predictive analytics to anticipate equipment failures and schedule maintenance proactively. This reduces downtime, improves asset utilization, and extends the lifespan of your equipment.

E. Sustainable Manufacturing Practices:

ERP software can help you implement sustainable manufacturing practices by tracking energy consumption, reducing waste, and optimizing resource utilization. This enables you to reduce your environmental impact and contribute to a more sustainable future.

Advantages and Disadvantages of ERP Software:

While ERP software offers numerous advantages for manufacturers, it’s essential to consider both the pros and cons before implementing a system.

Advantages of ERP Software:

- Improved Efficiency and Productivity: ERP software streamlines workflows, automates tasks, and provides real-time visibility into operations, leading to increased efficiency and productivity.

- Enhanced Decision-Making: ERP provides access to real-time data and analytics, enabling informed decision-making across all departments.

- Reduced Costs: ERP software optimizes resource utilization, minimizes waste, and automates processes, leading to reduced operational costs.

- Improved Customer Satisfaction: ERP software enhances customer service, streamlines order processing, and provides personalized interactions, leading to increased customer satisfaction.

- Increased Profitability: ERP software improves efficiency, reduces costs, and enhances customer satisfaction, leading to increased profitability and a stronger bottom line.

- Better Compliance and Risk Management: ERP software streamlines compliance processes, automates reporting, and provides insights into potential risks, ensuring compliance with regulations and minimizing potential liabilities.

- Scalability and Flexibility: ERP software can be scaled to meet the needs of growing businesses and can be customized to adapt to specific industry requirements.

Disadvantages of ERP Software:

- High Initial Investment: Implementing an ERP system can require a significant initial investment, including software licensing, hardware upgrades, and implementation costs.

- Complex Implementation: Implementing an ERP system can be a complex and time-consuming process, requiring extensive planning, training, and data migration.

- Potential for Disruptions: Implementing an ERP system can disrupt existing workflows and require employees to adapt to new processes, leading to potential disruptions and resistance to change.

- Customization and Integration Challenges: Customizing an ERP system to meet specific business needs and integrating it with existing systems can be challenging and require specialized expertise.

- Ongoing Maintenance and Support Costs: Once implemented, an ERP system requires ongoing maintenance, support, and upgrades, which can add to the overall cost of ownership.

Choosing the Right ERP Software for Your Business:

Selecting the right ERP software for your business is crucial for successful implementation. Consider the following factors when making your decision:

- Industry-Specific Functionality: Choose an ERP system that offers industry-specific functionality tailored to your specific needs.

- Scalability and Flexibility: Select an ERP system that can grow with your business and adapt to changing requirements.

- Integration Capabilities: Ensure the ERP system can integrate with your existing systems, such as CRM, accounting software, and production planning tools.

- User-Friendliness and Training: Choose an ERP system with a user-friendly interface and comprehensive training resources to ensure smooth adoption and minimize resistance to change.

- Vendor Support and Reputation: Select a vendor with a proven track record, excellent customer support, and a commitment to ongoing innovation.

Conclusion: Embracing the Future of Manufacturing with ERP

As we conclude our exploration of ERP software, it’s clear that this technology is no longer a luxury but a necessity for manufacturers looking to thrive in today’s competitive landscape. By embracing ERP, you can unlock a world of efficiency, productivity, and profitability, transforming your business and propelling it towards a brighter future.

Don’t let the complexities of manufacturing hold you back. Take the leap and explore the transformative power of ERP software. It’s time to embrace the future of manufacturing and unlock the full potential of your business.

Disclaimer: This article provides general information on ERP software and its potential benefits for manufacturers. Specific implementation details and outcomes may vary depending on individual business needs and the chosen ERP solution. It is always recommended to consult with industry experts and conduct thorough research before making any decisions regarding ERP implementation.

FAQs:

1. What are the key features of a manufacturing ERP system?

A manufacturing ERP system typically includes modules for production planning and scheduling, inventory management, supply chain management, customer relationship management (CRM), financial management, and business intelligence.

2. How does ERP software improve production efficiency?

ERP software improves production efficiency by streamlining workflows, automating tasks, providing real-time visibility into operations, and optimizing resource utilization.

3. What are the benefits of using an ERP system for inventory management?

ERP software helps manufacturers optimize inventory management by providing real-time visibility into inventory levels, minimizing stockouts and excess inventory, streamlining procurement processes, and improving material planning and forecasting.

4. How can ERP software help manufacturers manage their supply chain?

ERP software enhances supply chain management by providing real-time visibility into the supply chain, streamlining supplier management, improving collaboration with suppliers, reducing lead times, and enhancing risk management.

5. What are the advantages of using an ERP system for financial management?

ERP software improves financial management by providing real-time financial insights, streamlining accounting processes, enhancing financial reporting, and improving compliance and audit readiness.

6. How can ERP software help manufacturers adapt to Industry 4.0?

ERP software is evolving to integrate with emerging technologies such as the Internet of Things (IoT), artificial intelligence (AI), and cloud computing, enabling manufacturers to leverage these technologies to improve their operations, enhance efficiency, and gain a competitive advantage.

7. What are the common challenges associated with implementing an ERP system?

Common challenges associated with implementing an ERP system include high initial investment, complex implementation, potential for disruptions, customization and integration challenges, and ongoing maintenance and support costs.

8. How can I choose the right ERP software for my business?

When choosing an ERP system, consider factors such as industry-specific functionality, scalability and flexibility, integration capabilities, user-friendliness, vendor support, and reputation.

9. What are the key factors to consider when evaluating ERP vendors?

When evaluating ERP vendors, consider their experience, industry expertise, customer support, track record, pricing, and commitment to innovation.

10. How can I ensure a successful ERP implementation?

To ensure a successful ERP implementation, involve key stakeholders, define clear goals and objectives, develop a comprehensive implementation plan, provide adequate training, and manage change effectively.

11. What are the best practices for using ERP software?

Best practices for using ERP software include establishing clear processes, providing regular training, monitoring key performance indicators, and leveraging the system’s reporting and analytics capabilities.

12. What are the future trends in ERP software for manufacturing?

Future trends in ERP software for manufacturing include increased integration with emerging technologies, enhanced data analytics capabilities, and greater focus on sustainability and Industry 4.0 initiatives.

13. How can ERP software help manufacturers improve their sustainability efforts?

ERP software can help manufacturers improve their sustainability efforts by tracking energy consumption, reducing waste, optimizing resource utilization, and reporting on environmental performance.

.

.