Finding the Perfect Fit: Your Guide to Choosing the Best ERP for Manufacturing

.

.

Greetings, fellow manufacturers! In the dynamic world of manufacturing, where efficiency, agility, and innovation are paramount, a robust Enterprise Resource Planning (ERP) system is no longer a luxury but a necessity. It’s the backbone that orchestrates your entire business, from raw materials procurement to finished product delivery, ensuring seamless operations and optimal performance.

But navigating the vast landscape of ERP solutions can feel like traversing a complex maze. With countless options vying for your attention, choosing the right ERP for your manufacturing business can seem daunting. This comprehensive guide aims to illuminate the path, empowering you to make an informed decision that aligns with your unique needs and aspirations.

The Quest for the Ideal ERP: A Journey of Discovery

Imagine a world where your manufacturing processes are streamlined, data flows effortlessly, and every department operates in perfect harmony. This is the promise of a well-implemented ERP system. But achieving this utopia requires meticulous planning and a deep understanding of your business’s specific requirements.

.

.

Unveiling Your Manufacturing Needs: A Crucial First Step

Before embarking on your ERP search, take a moment to introspect. What are the key challenges you face in your manufacturing operations? Are you grappling with inventory management inefficiencies, struggling to maintain accurate production schedules, or experiencing difficulties in tracking your costs?

Tailoring Your ERP Solution: A Symphony of Customization

The best ERP for your manufacturing business is not a one-size-fits-all solution. It’s a tailored system that addresses your unique pain points and empowers you to achieve your strategic goals. This requires a careful evaluation of your specific needs, from production planning and scheduling to quality control and customer relationship management.

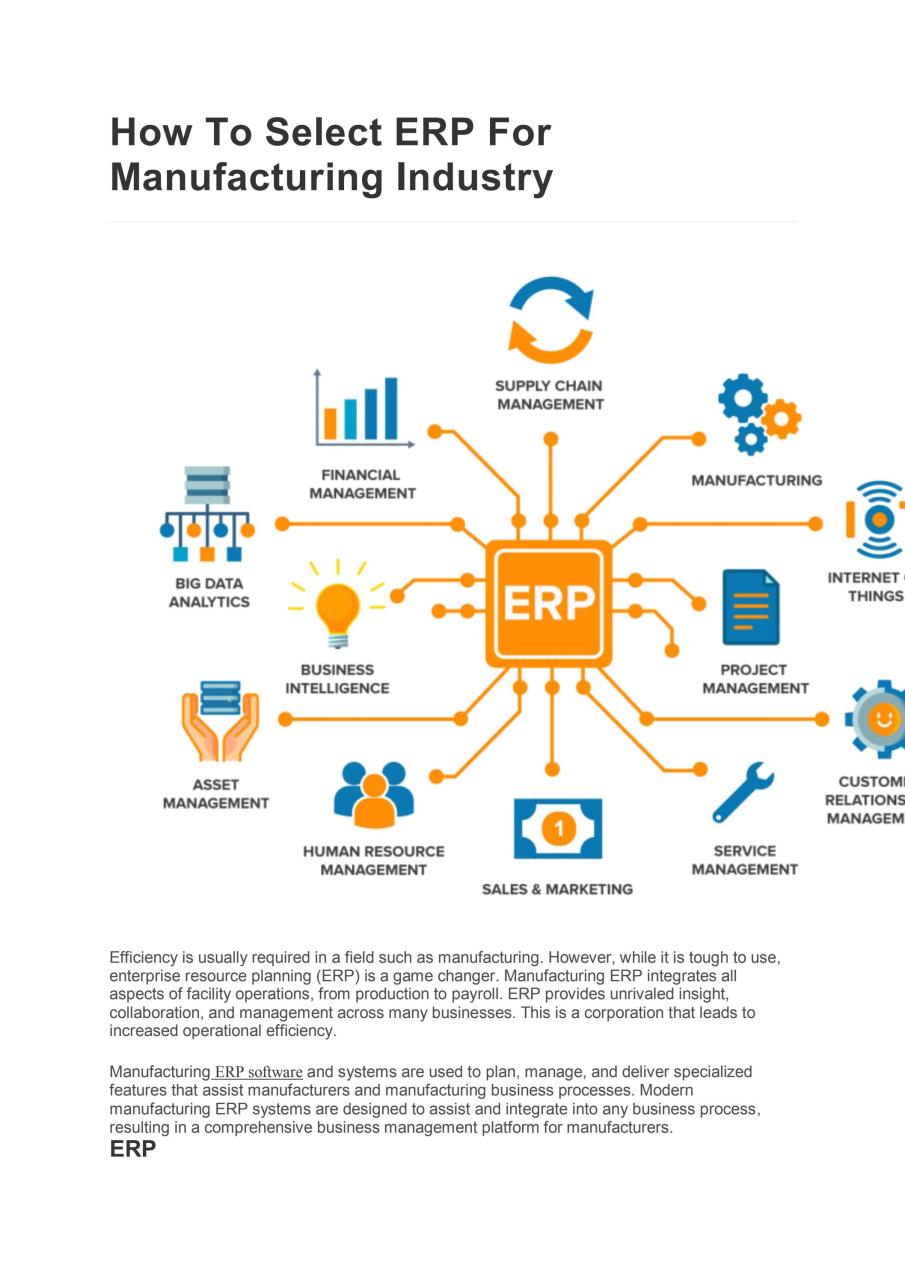

The Power of Integration: Breaking Down Silos and Fostering Collaboration

A key advantage of an ERP system is its ability to integrate various business functions, breaking down silos and fostering seamless collaboration. By connecting departments like production, finance, and sales, ERP systems create a unified platform for information sharing and decision-making.

.

.

Data-Driven Insights: Unlocking the Potential of Your Manufacturing Operations

Modern ERP systems are data-driven powerhouses, providing real-time insights into your manufacturing processes. From production performance metrics to inventory levels and customer demand, ERP systems equip you with the data you need to make informed decisions and optimize your operations.

Embracing the Future: The Evolution of ERP in Manufacturing

The manufacturing landscape is constantly evolving, driven by advancements in technology, changing consumer demands, and global economic shifts. To stay ahead of the curve, your ERP system must be adaptable and scalable, enabling you to embrace new technologies and respond to market fluctuations with agility.

Navigating the ERP Landscape: A Comprehensive Guide

.

.

1. Defining Your ERP Requirements: A Foundation for Success

Understanding Your Business Needs:

The first step in your ERP journey is to define your specific requirements. What are the key challenges you face in your manufacturing operations? Are you struggling with inventory management inefficiencies, production scheduling issues, or difficulties in tracking costs?

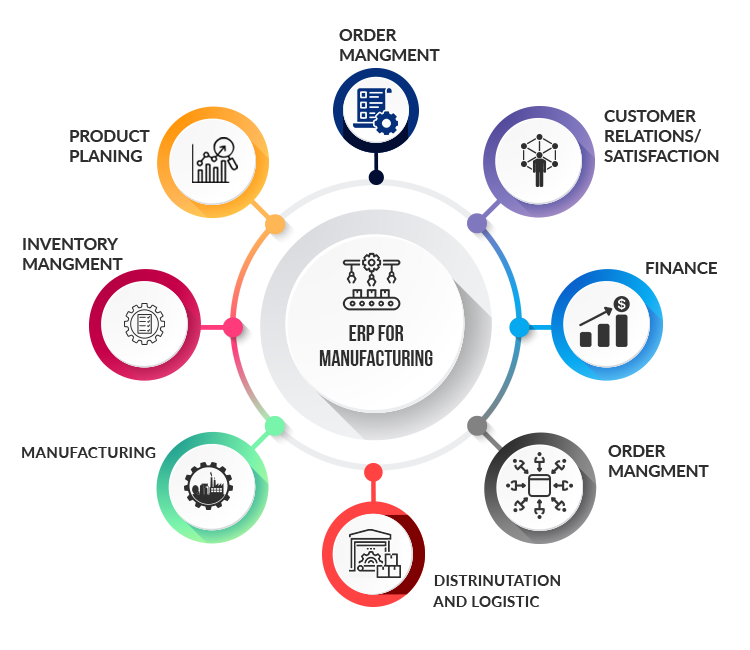

Identifying Key Business Processes:

Once you’ve identified your challenges, map out your key business processes. This includes everything from raw material procurement and production planning to quality control, shipping, and customer service.

.

.

Defining Your ERP Goals:

What do you hope to achieve with an ERP system? Do you want to improve efficiency, reduce costs, enhance visibility, or gain a competitive edge? Clearly define your goals to guide your ERP selection.

2. Types of ERP Systems for Manufacturing: A Comprehensive Overview

Cloud-Based ERP Systems:

Cloud-based ERP systems are hosted on remote servers and accessed through the internet. They offer flexibility, scalability, and affordability, making them a popular choice for manufacturers of all sizes.

.

.

On-Premise ERP Systems:

On-premise ERP systems are installed and maintained on your own servers. They offer greater control and security but require significant upfront investment and ongoing maintenance.

Hybrid ERP Systems:

Hybrid ERP systems combine the benefits of both cloud-based and on-premise solutions. They allow you to deploy certain modules in the cloud while keeping others on-premise, offering a flexible and cost-effective approach.

3. Key Features of an ERP System for Manufacturing: A Detailed Exploration

Production Planning and Scheduling:

An ERP system helps you plan and schedule production efficiently, ensuring that you meet customer demand while optimizing resource utilization.

Inventory Management:

ERP systems provide real-time visibility into your inventory levels, helping you optimize stock levels, reduce waste, and prevent stockouts.

Quality Control:

ERP systems enable you to track and manage quality control processes, ensuring that your products meet industry standards and customer expectations.

Financial Management:

ERP systems integrate financial data from various departments, providing a comprehensive view of your financial performance.

Customer Relationship Management (CRM):

ERP systems can integrate with CRM systems, providing a 360-degree view of your customers and enabling you to personalize your interactions.

4. Choosing the Right ERP Vendor: A Strategic Decision

Industry Expertise:

Look for a vendor with deep industry expertise in manufacturing. They should understand your specific challenges and offer tailored solutions.

Implementation Expertise:

Choose a vendor with a proven track record of successful ERP implementations. They should have experienced consultants who can guide you through the process.

Support and Training:

Ensure that the vendor provides ongoing support and training to help you maximize the benefits of your ERP system.

5. ERP Implementation: A Comprehensive Guide

Planning and Scoping:

The first step in the implementation process is to define the scope of your project and develop a detailed implementation plan.

Data Migration:

Transferring your existing data to the new ERP system is a critical step. Ensure that the data is accurate and complete.

User Training:

Train your employees on the new ERP system to ensure that they can use it effectively.

Go-Live and Support:

The go-live phase is the culmination of your implementation efforts. After go-live, the vendor should provide ongoing support to address any issues.

6. Benefits of Implementing an ERP System: A Transformative Impact

Improved Efficiency:

ERP systems streamline your manufacturing processes, reducing waste, minimizing downtime, and improving overall efficiency.

Reduced Costs:

By optimizing inventory levels, streamlining operations, and automating tasks, ERP systems can help you reduce costs significantly.

Enhanced Visibility:

ERP systems provide real-time visibility into your operations, enabling you to make informed decisions based on accurate data.

Increased Agility:

ERP systems help you respond quickly to market changes and customer demands, enabling you to stay ahead of the competition.

7. Challenges of Implementing an ERP System: Overcoming Obstacles

Cost:

Implementing an ERP system can be expensive, requiring significant upfront investment.

Complexity:

ERP systems are complex, requiring careful planning and execution.

Change Management:

Employees may resist change, so it’s crucial to manage the transition effectively.

Data Integration:

Integrating data from various sources can be challenging.

8. Best ERP Systems for Manufacturing: A Comprehensive Review

SAP:

SAP is a global leader in ERP solutions, offering a comprehensive suite of modules for manufacturing businesses.

Oracle:

Oracle is another major ERP vendor, providing a wide range of solutions for manufacturing companies of all sizes.

Microsoft Dynamics 365:

Microsoft Dynamics 365 is a cloud-based ERP system designed for small and medium-sized businesses.

Infor:

Infor specializes in industry-specific ERP solutions, including manufacturing.

Epicor:

Epicor is a leading provider of ERP solutions for the manufacturing industry, offering a wide range of modules.

9. The Future of ERP in Manufacturing: Embracing Innovation

Artificial Intelligence (AI):

AI is transforming ERP systems, enabling intelligent automation, predictive analytics, and enhanced decision-making.

Internet of Things (IoT):

IoT devices are connecting manufacturing equipment, providing real-time data and enabling remote monitoring and control.

Cloud Computing:

Cloud-based ERP systems are becoming increasingly popular, offering flexibility, scalability, and affordability.

10. Choosing the Right ERP for Your Manufacturing Business: A Decision Framework

Define Your Needs:

Clearly identify your specific requirements and challenges.

Research ERP Vendors:

Evaluate different ERP vendors based on industry expertise, implementation experience, and support.

Request Demonstrations:

Request demos from shortlisted vendors to see how their solutions work in practice.

Get Quotes and Compare:

Obtain quotes from different vendors and compare their pricing and features.

11. ERP Implementation Best Practices: A Roadmap for Success

Engage Key Stakeholders:

Involve all relevant departments and stakeholders in the implementation process.

Define Clear Roles and Responsibilities:

Assign clear roles and responsibilities to ensure a smooth implementation.

Train Your Employees:

Provide comprehensive training to ensure that employees can use the new system effectively.

Test Thoroughly:

Thoroughly test the system before going live to identify and address any issues.

12. Optimizing Your ERP Investment: Maximizing Value

Regularly Review and Update:

Review your ERP system regularly to ensure it continues to meet your evolving needs.

Utilize All Features:

Explore all the features of your ERP system to maximize its value.

Seek Support When Needed:

Don’t hesitate to contact your vendor for support when needed.

13. Conclusion: Empowering Your Manufacturing Success

Choosing the right ERP system is a critical decision that can significantly impact your manufacturing business. By following the steps outlined in this guide, you can navigate the ERP landscape effectively and find a solution that empowers your success.

Remember, the journey towards finding the perfect ERP for your manufacturing business is a collaborative effort. Engage your team, consult with experts, and embrace the transformative power of technology to unlock the full potential of your operations.

Disclaimer: This article is intended to provide general information about ERP systems for manufacturing. It is not a substitute for professional advice. Please consult with a qualified ERP consultant to determine the best solution for your specific needs.

.

.