Unlocking Efficiency and Growth: Your Guide to the Best Manufacturing ERP Solutions

.

.

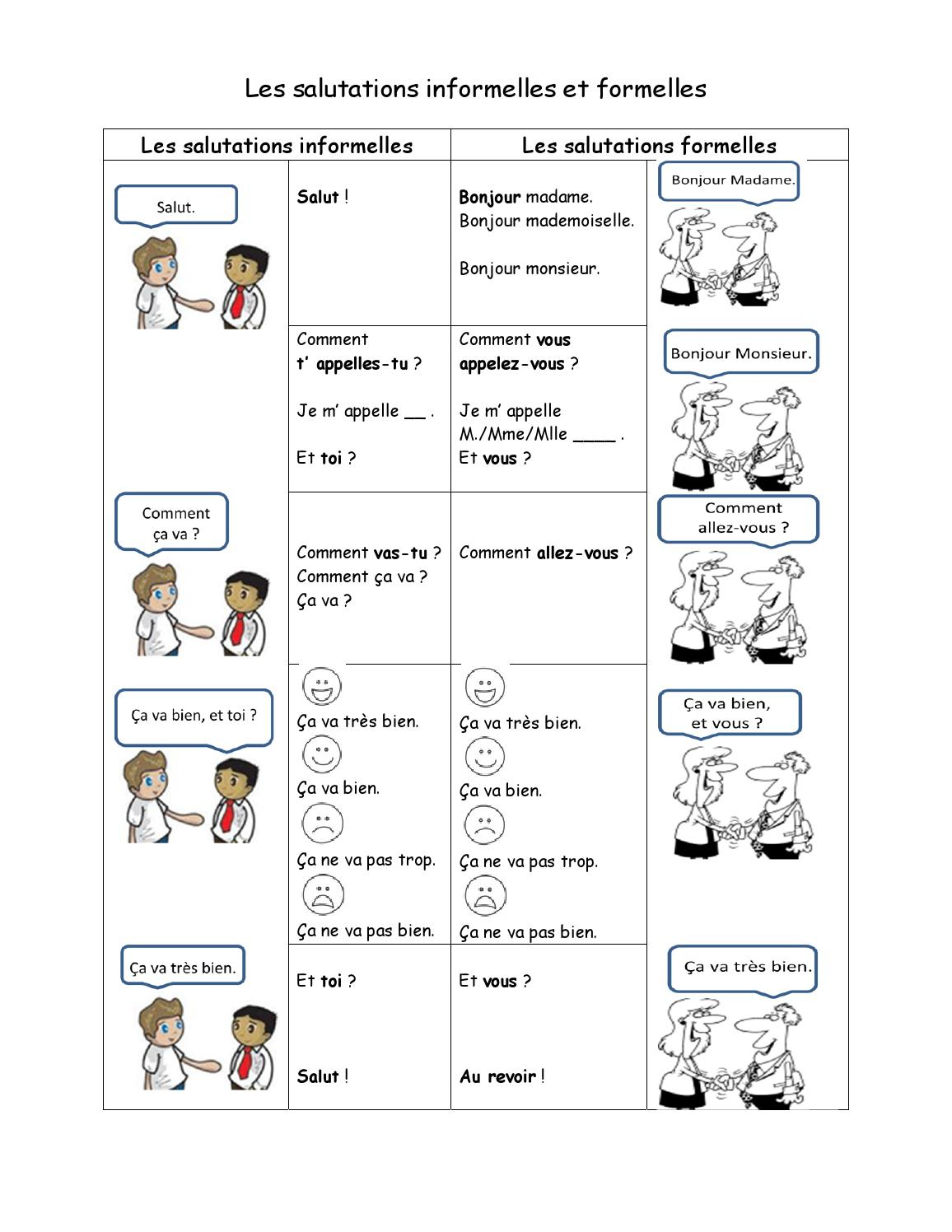

Welcome, fellow manufacturers! In today’s dynamic and competitive landscape, staying ahead of the curve is paramount. Efficiency, agility, and data-driven decision-making are no longer mere aspirations but essential ingredients for survival and success. This is where the power of a robust Manufacturing Enterprise Resource Planning (ERP) system comes into play.

Imagine a centralized platform that seamlessly integrates your entire manufacturing operation, from raw material procurement to finished goods delivery, providing real-time insights into every aspect of your business. This is the promise of a well-implemented Manufacturing ERP, a digital backbone that empowers you to optimize processes, enhance visibility, and unlock unparalleled growth potential.

But navigating the vast and complex world of Manufacturing ERP solutions can be daunting. With so many options available, how do you identify the best fit for your unique needs and challenges? This comprehensive guide will demystify the landscape, providing you with the knowledge and insights to make informed decisions. We’ll explore the key features, benefits, and considerations that will help you choose the perfect Manufacturing ERP solution to propel your business to new heights.

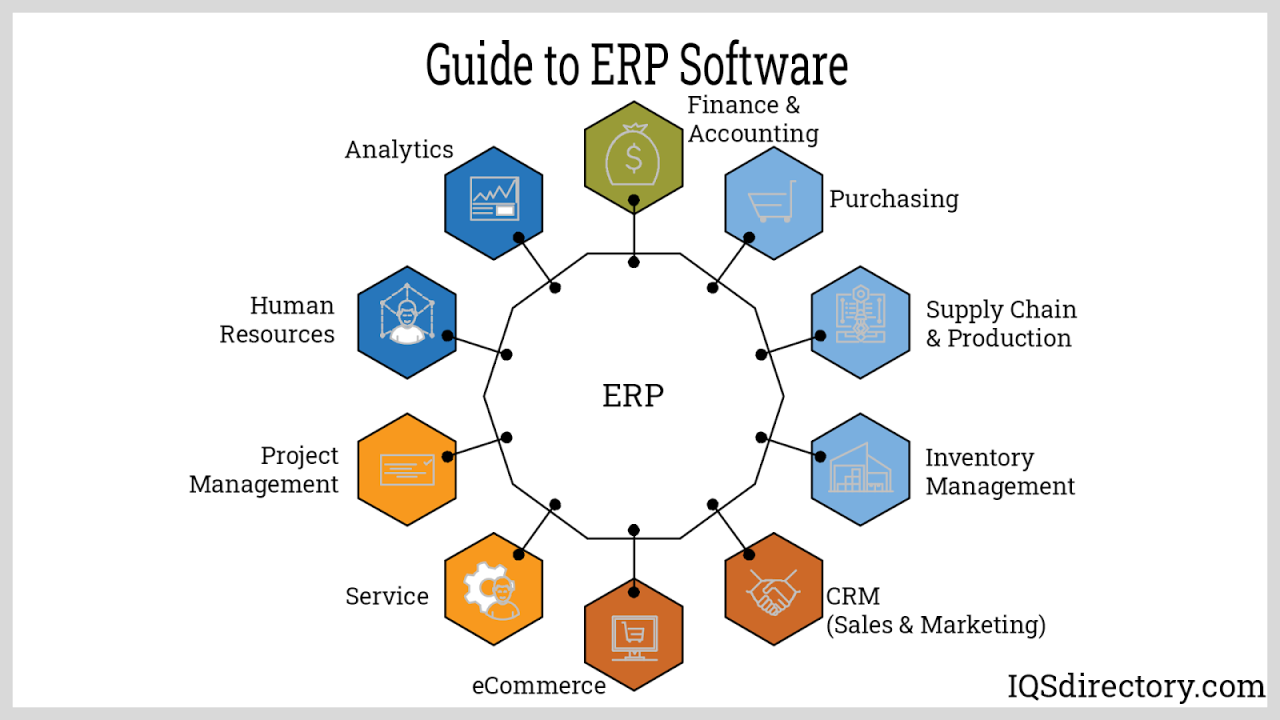

Let’s begin by understanding the core functionalities that make a Manufacturing ERP system indispensable. At its heart, a Manufacturing ERP solution acts as a central nervous system, connecting and streamlining every aspect of your production process. From managing inventory levels and production planning to tracking customer orders and managing finances, a robust ERP system provides a unified platform for all your critical business operations.

.

.

The Power of Integration: Breaking Down Silos for Enhanced Efficiency

One of the most significant advantages of a Manufacturing ERP system is its ability to break down information silos and create a unified flow of data across your entire organization. Imagine a scenario where your sales team has no visibility into current inventory levels, leading to inaccurate delivery promises and frustrated customers. A Manufacturing ERP system eliminates this problem by providing real-time access to critical data, ensuring everyone is on the same page and working towards common goals.

Real-Time Visibility: Empowering Data-Driven Decisions

In the fast-paced world of manufacturing, timely and accurate information is crucial for making informed decisions. A well-implemented Manufacturing ERP system provides real-time visibility into key metrics, enabling you to track progress, identify bottlenecks, and make adjustments on the fly. This data-driven approach empowers you to optimize production processes, minimize downtime, and ensure that your operations run smoothly and efficiently.

Streamlined Processes: From Order to Delivery, Seamlessly

Manufacturing ERP systems streamline your entire production process, from order placement to final delivery. With automated workflows and integrated modules, you can eliminate manual tasks, reduce errors, and accelerate the entire production cycle. This efficiency translates into faster turnaround times, improved customer satisfaction, and increased profitability.

.

.

Enhanced Collaboration: Breaking Down Barriers for Team Success

Collaboration is key to success in any manufacturing operation. A Manufacturing ERP system facilitates seamless communication and collaboration among your teams, regardless of their location. With shared access to data, everyone can stay informed, work together effectively, and achieve common goals. This collaborative environment fosters a culture of transparency and accountability, driving overall productivity and success.

Financial Management: Gaining Control Over Your Bottom Line

Financial management is an integral part of any manufacturing business. A Manufacturing ERP system provides comprehensive tools for managing your finances, from tracking expenses and revenue to generating financial reports and forecasting future performance. This centralized financial management platform gives you complete control over your bottom line, enabling you to make informed decisions and optimize your profitability.

The Evolution of Manufacturing ERP: From On-Premise to Cloud-Based Solutions

.

.

The world of Manufacturing ERP has undergone a significant evolution in recent years, with cloud-based solutions gaining increasing popularity. Traditional on-premise ERP systems required significant upfront investment and ongoing maintenance, making them a less attractive option for many businesses. Cloud-based ERP solutions, on the other hand, offer a more flexible and cost-effective approach, providing access to powerful features and functionalities without the need for extensive hardware and software infrastructure.

Choosing the Right Manufacturing ERP Solution: A Tailored Approach

With so many options available, choosing the right Manufacturing ERP solution can be a daunting task. However, by considering your specific needs and requirements, you can narrow down the field and identify the best fit for your business. Here are some key factors to consider:

1. Industry-Specific Needs: Tailoring Solutions for Unique Requirements

Different industries have unique requirements and challenges. For example, a manufacturing company producing high-volume consumer goods will have different needs than a manufacturer of specialized medical devices. When choosing a Manufacturing ERP solution, it’s essential to select one that caters to your industry-specific requirements and provides the necessary functionalities to support your operations.

.

.

2. Business Size and Growth Potential: Scaling Up with Your Needs

The size of your business and your growth plans are crucial factors to consider. A small-scale manufacturer may find that a basic ERP solution meets their current needs, while a larger company may require a more comprehensive and scalable system. Ensure that the chosen ERP solution can grow with your business, providing the necessary flexibility and capacity to accommodate future expansion.

3. Budget and Implementation Costs: Finding the Right Balance

The cost of a Manufacturing ERP solution can vary significantly depending on the features, functionalities, and vendor. It’s essential to develop a realistic budget and consider the implementation costs, including training, customization, and ongoing support. Don’t compromise on quality or functionality but also be mindful of the financial implications of your choice.

4. Integration with Existing Systems: Seamlessly Connecting Your Technology Landscape

.

.

If you already have existing systems in place, such as CRM, accounting software, or warehouse management systems, it’s crucial to ensure that the chosen ERP solution can integrate seamlessly. This integration will prevent data silos, streamline workflows, and ensure that all your systems work together harmoniously.

5. Vendor Reputation and Support: Choosing a Trusted Partner for Success

The vendor’s reputation and support capabilities are critical factors to consider. Choose a reputable vendor with a proven track record of successful implementations and a strong commitment to customer satisfaction. Ensure that they provide comprehensive training, documentation, and ongoing support to help you maximize the value of your investment.

The Advantages of Implementing a Manufacturing ERP System

The benefits of implementing a Manufacturing ERP system are numerous and far-reaching, impacting every aspect of your business. Here’s a comprehensive look at the key advantages:

1. Enhanced Efficiency: Streamlining Operations for Maximum Productivity

A Manufacturing ERP system streamlines your entire production process, automating tasks, reducing errors, and eliminating bottlenecks. This streamlined approach leads to increased efficiency, reduced waste, and higher productivity, ultimately boosting your bottom line.

2. Improved Visibility: Gaining Real-Time Insights for Data-Driven Decisions

With a Manufacturing ERP system, you gain real-time visibility into every aspect of your operation, from inventory levels and production schedules to customer orders and financial performance. This data-driven approach empowers you to make informed decisions, optimize processes, and identify areas for improvement.

3. Reduced Costs: Optimizing Resources and Minimizing Waste

By streamlining processes, automating tasks, and eliminating errors, a Manufacturing ERP system helps you optimize resource allocation and minimize waste. This leads to significant cost savings, improving your profitability and allowing you to reinvest in growth and innovation.

4. Improved Customer Satisfaction: Delivering Products on Time and Meeting Expectations

A Manufacturing ERP system helps you deliver products on time and meet customer expectations by providing real-time visibility into orders, production schedules, and inventory levels. This improved accuracy and responsiveness enhance customer satisfaction and build lasting relationships.

5. Enhanced Collaboration: Fostering Teamwork and Communication for Success

A Manufacturing ERP system fosters seamless communication and collaboration among your teams, regardless of their location. With shared access to data, everyone can stay informed, work together effectively, and achieve common goals. This collaborative environment drives overall productivity and success.

The Disadvantages of Implementing a Manufacturing ERP System

While the benefits of a Manufacturing ERP system are undeniable, it’s important to acknowledge the potential disadvantages. Here’s a balanced perspective:

1. Implementation Costs: A Significant Investment with Long-Term Returns

Implementing a Manufacturing ERP system can be a significant investment, requiring upfront costs for software licenses, hardware, customization, and training. However, the long-term benefits, including increased efficiency, reduced costs, and improved customer satisfaction, far outweigh the initial investment.

2. Complexity: Navigating the intricacies of a Powerful System

Manufacturing ERP systems can be complex, requiring time and effort to learn and master. It’s essential to invest in adequate training for your team and provide ongoing support to ensure that they can effectively use the system and realize its full potential.

3. Customization: Tailoring the System to Your Specific Needs

Customizing a Manufacturing ERP system to meet your specific requirements can be time-consuming and costly. While customization can enhance the system’s functionality and streamline workflows, it’s important to carefully consider the trade-offs between customization and implementation costs.

4. Data Migration: Moving Your Data to a New System

Migrating your existing data to a new Manufacturing ERP system can be a challenging and time-consuming process. It’s essential to plan carefully, ensure data accuracy, and minimize disruption to your operations during the migration process.

5. Integration Challenges: Connecting with Existing Systems

Integrating a Manufacturing ERP system with your existing systems, such as CRM, accounting software, or warehouse management systems, can be complex and require specialized expertise. It’s crucial to ensure that the chosen ERP solution can integrate seamlessly with your existing technology landscape to avoid data silos and streamline workflows.

Choosing the Right Manufacturing ERP Solution: A Step-by-Step Guide

Now that you have a comprehensive understanding of the advantages and disadvantages of implementing a Manufacturing ERP system, let’s delve into the practical steps involved in choosing the right solution for your business.

1. Define Your Business Needs: Identifying Your Specific Requirements

Begin by defining your specific business needs and challenges. What are your key goals? What processes are you looking to improve? What data do you need to track and analyze? By clearly defining your requirements, you can narrow down the field of potential ERP solutions and focus on those that best align with your needs.

2. Research and Evaluate Potential Vendors: Comparing Features and Functionalities

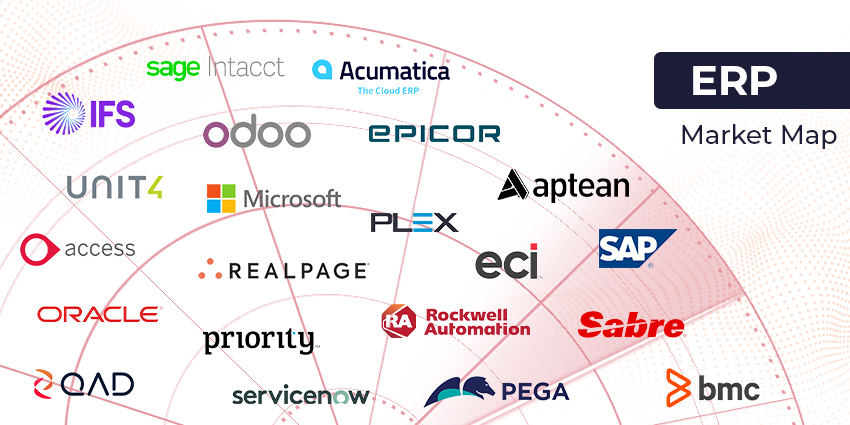

Once you have a clear understanding of your requirements, research and evaluate potential ERP vendors. Compare their features, functionalities, industry experience, and customer support capabilities. Look for vendors that offer solutions tailored to your industry and business size and provide a proven track record of successful implementations.

3. Request Demonstrations and Consult with Experts: Gaining Hands-On Experience

Request demonstrations from shortlisted vendors to see their ERP solutions in action. This hands-on experience will give you a better understanding of the user interface, features, and functionalities. Consult with industry experts to gain insights and perspectives on the different solutions and vendors.

4. Consider Implementation Costs and Support: Balancing Functionality and Budget

Evaluate the implementation costs, including software licenses, hardware, customization, and training. Also, consider the ongoing support costs, such as maintenance, upgrades, and technical assistance. Balance the functionality and features of the ERP solution with your budget and long-term financial considerations.

5. Make an Informed Decision: Choosing the Best Fit for Your Business

After careful consideration, make an informed decision based on your business needs, vendor reputation, implementation costs, and long-term support capabilities. Choose the ERP solution that best aligns with your goals and provides the necessary functionalities to drive your business forward.

Key Features of a Robust Manufacturing ERP System

A robust Manufacturing ERP system encompasses a wide range of functionalities to manage every aspect of your operation. Here are some key features to look for:

1. Production Planning and Scheduling: Optimizing Resources and Meeting Deadlines

A robust Manufacturing ERP system provides powerful tools for production planning and scheduling, allowing you to optimize resource allocation, manage production schedules, and meet deadlines. Features such as Material Requirements Planning (MRP) and Capacity Planning help you ensure that you have the necessary materials and resources to meet production demands.

2. Inventory Management: Tracking Stock Levels and Minimizing Waste

Effective inventory management is crucial for any manufacturing business. A Manufacturing ERP system provides real-time visibility into inventory levels, enabling you to track stock movements, manage replenishment, and minimize waste. Features such as ABC analysis and cycle counting help you optimize inventory levels and reduce storage costs.

3. Quality Control: Ensuring Product Excellence and Meeting Standards

Quality control is paramount in manufacturing. A Manufacturing ERP system provides tools for tracking and managing quality control processes, ensuring that your products meet industry standards and customer expectations. Features such as non-conformance reporting and root cause analysis help you identify and address quality issues proactively.

4. Customer Relationship Management (CRM): Building Strong Relationships and Driving Sales

A Manufacturing ERP system with integrated CRM capabilities allows you to manage customer interactions, track sales opportunities, and provide excellent customer service. Features such as lead management, opportunity tracking, and customer support tools help you build strong relationships and drive sales.

5. Financial Management: Gaining Control Over Your Bottom Line

Comprehensive financial management is essential for any manufacturing business. A Manufacturing ERP system provides tools for managing your finances, from tracking expenses and revenue to generating financial reports and forecasting future performance. Features such as budgeting, forecasting, and financial reporting help you gain complete control over your bottom line.

FAQs: Addressing Common Questions about Manufacturing ERP Systems

1. What is the difference between an ERP system and a Manufacturing ERP system?

A traditional ERP system provides a broad range of functionalities for managing various business processes, including finance, human resources, and sales. A Manufacturing ERP system is specifically designed for the unique needs of manufacturing businesses, offering features and functionalities tailored to production planning, inventory management, quality control, and other manufacturing-specific processes.

2. How much does a Manufacturing ERP system cost?

The cost of a Manufacturing ERP system can vary significantly depending on the features, functionalities, and vendor. Factors such as business size, industry-specific requirements, and implementation costs can influence the overall price. It’s essential to research and compare different vendors to find a solution that fits your budget and provides the necessary functionalities.

3. How long does it take to implement a Manufacturing ERP system?

The implementation timeline for a Manufacturing ERP system can vary depending on the complexity of the system, the size of your business, and the level of customization required. On average, implementation can take anywhere from a few months to a year or more. It’s important to plan carefully, allocate sufficient resources, and involve key stakeholders throughout the implementation process.

4. What are the key benefits of implementing a Manufacturing ERP system?

The benefits of implementing a Manufacturing ERP system are numerous and far-reaching, impacting every aspect of your business. Key benefits include enhanced efficiency, improved visibility, reduced costs, improved customer satisfaction, and enhanced collaboration.

5. What are the potential challenges of implementing a Manufacturing ERP system?

While the benefits of a Manufacturing ERP system are undeniable, it’s important to acknowledge the potential challenges. These include implementation costs, complexity, customization requirements, data migration, and integration challenges. Careful planning, resource allocation, and vendor selection are crucial to mitigate these challenges.

6. How do I choose the right Manufacturing ERP system for my business?

Choosing the right Manufacturing ERP system requires careful consideration of your specific business needs, industry requirements, budget, and vendor reputation. It’s essential to research and evaluate different vendors, request demonstrations, and consult with industry experts to make an informed decision.

7. What are some of the key features to look for in a Manufacturing ERP system?

Key features to look for in a Manufacturing ERP system include production planning and scheduling, inventory management, quality control, customer relationship management (CRM), and financial management. Ensure that the chosen solution provides the necessary functionalities to support your specific business processes.

8. What are some of the best Manufacturing ERP systems available?

There are numerous reputable Manufacturing ERP systems available, each with its own strengths and weaknesses. Some popular options include SAP, Oracle, Infor, Epicor, and Microsoft Dynamics 365. It’s essential to research and compare different vendors to find the best fit for your business.

9. What are some tips for successful implementation of a Manufacturing ERP system?

Successful implementation of a Manufacturing ERP system requires careful planning, resource allocation, and stakeholder involvement. It’s essential to define your business needs, choose the right vendor, allocate sufficient resources, and provide adequate training to your team.

10. How can I ensure that my team is effectively using the Manufacturing ERP system?

Ensure that your team is effectively using the Manufacturing ERP system by providing adequate training, documentation, and ongoing support. Encourage feedback and address any challenges or concerns promptly. Regularly monitor system usage and performance to identify areas for improvement.

11. What are the future trends in Manufacturing ERP?

Future trends in Manufacturing ERP include the increasing adoption of cloud-based solutions, the integration of artificial intelligence (AI) and machine learning (ML), and the focus on Industry 4.0 technologies, such as the Internet of Things (IoT) and smart factories.

12. What are the benefits of using a cloud-based Manufacturing ERP system?

Cloud-based Manufacturing ERP systems offer several benefits, including lower upfront costs, increased flexibility, scalability, and accessibility. They also provide access to the latest features and functionalities without the need for extensive hardware and software infrastructure.

13. How can I get started with implementing a Manufacturing ERP system?

To get started with implementing a Manufacturing ERP system, begin by defining your business needs, researching potential vendors, and requesting demonstrations. Consult with industry experts, evaluate implementation costs, and make an informed decision based on your specific requirements.

Conclusion: Embracing the Power of Manufacturing ERP for Unparalleled Growth

In a world where efficiency, agility, and data-driven decision-making are paramount, a robust Manufacturing ERP system is no longer a luxury but a necessity. By leveraging the power of a well-implemented ERP solution, you can unlock unparalleled growth potential, optimize your operations, and gain a competitive edge.

Remember, choosing the right Manufacturing ERP solution is a critical decision that will have a significant impact on your business. By carefully considering your specific needs, industry requirements, budget, and vendor reputation, you can make an informed choice that will empower you to achieve your business goals and propel your manufacturing operation to new heights.

Don’t hesitate to embrace the transformative power of Manufacturing ERP. Take the first step today and embark on a journey of efficiency, growth, and success.

Disclaimer: This article is intended to provide general information and insights about Manufacturing ERP systems and should not be considered as professional advice. It’s essential to consult with industry experts and conduct thorough research to make informed decisions that align with your specific business needs and requirements. The information provided in this article is subject to change and should be verified with the appropriate sources.

.

.