The Goal of Inventory Management: Unveiling the Key Objectives and Strategies for Effective Stock Control

Inventory management plays a pivotal role in the seamless functioning of any organization, regardless of its size or industry. It encompasses a wide range of activities, from forecasting demand and managing stock levels to optimizing storage space and ensuring efficient order fulfillment. The overarching goal of inventory management is to strike a delicate balance between meeting customer demand and minimizing costs.

Understanding the Importance of Inventory Management

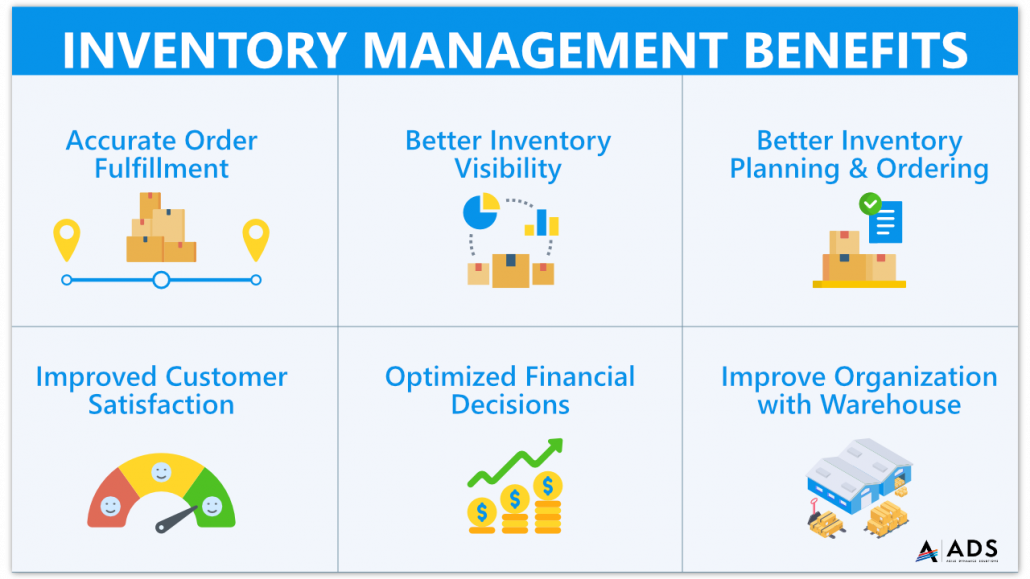

Inventory management is not merely about tracking the number of items in stock; it delves into the heart of supply chain operations, influencing factors such as customer satisfaction, operational efficiency, and financial performance. Effective inventory management practices can lead to:

- Enhanced customer satisfaction: By maintaining optimal stock levels, businesses can fulfill customer orders promptly, reducing the likelihood of stockouts and backorders.

- Improved operational efficiency: Streamlined inventory management processes minimize waste, reduce storage costs, and enhance overall supply chain visibility.

- Optimized financial performance: Prudent inventory management strategies help businesses minimize carrying costs, prevent losses due to spoilage or obsolescence, and optimize cash flow.

Key Objectives of Inventory Management

The primary objectives of inventory management revolve around achieving the aforementioned benefits. These objectives include:

- Maintaining optimal stock levels: Striking the right balance between overstocking and understocking is crucial to avoid stockouts and minimize carrying costs.

- Minimizing carrying costs: Inventory holding costs can be substantial, so businesses aim to keep them as low as possible without compromising service levels.

- Maximizing customer service: Meeting customer demand promptly and efficiently is paramount to building customer loyalty and driving repeat business.

- Improving supply chain efficiency: Effective inventory management ensures smooth coordination between suppliers, manufacturers, and distributors, reducing lead times and optimizing overall supply chain performance.

- Reducing waste and obsolescence: Proper inventory management practices help businesses identify and dispose of slow-moving or obsolete items, minimizing losses and optimizing stock turnover.

Strategies for Effective Inventory Management

Achieving the objectives of inventory management requires a combination of strategies and techniques. Some common approaches include:

- Demand forecasting: Predicting future demand accurately is essential for maintaining optimal stock levels and minimizing the risk of stockouts.

- Inventory classification: Categorizing inventory items based on factors such as demand, value, and perishability helps businesses prioritize inventory management efforts.

- Safety stock management: Maintaining a buffer stock of critical items ensures uninterrupted operations during periods of high demand or supply disruptions.

- Just-in-time (JIT) inventory: This approach aims to minimize inventory holding costs by receiving goods only when they are needed for production or sale.

- Vendor-managed inventory (VMI): In this arrangement, suppliers manage inventory levels on behalf of their customers, ensuring optimal stock levels and reducing the burden on the customer.

Advantages and Disadvantages of Inventory Management

Like any business practice, inventory management has its advantages and disadvantages.

Advantages:

- Improved customer service: Optimal stock levels lead to reduced stockouts and faster order fulfillment, enhancing customer satisfaction.

- Reduced costs: Effective inventory management minimizes carrying costs, storage costs, and waste, improving profitability.

- Enhanced supply chain efficiency: Streamlined inventory processes reduce lead times, improve coordination, and optimize overall supply chain performance.

- Increased sales: By ensuring product availability, businesses can capture more sales and grow their revenue.

- Improved decision-making: Accurate inventory data provides valuable insights for informed decision-making in areas such as production planning and purchasing.

Disadvantages:

- Carrying costs: Holding inventory incurs costs such as storage, insurance, and handling, which can impact profitability.

- Risk of obsolescence: Slow-moving or perishable items may become obsolete, leading to losses and reduced inventory turnover.

- Complexity: Inventory management can be complex, especially for businesses with a large number of SKUs or complex supply chains.

- Potential for errors: Manual inventory management processes are prone to errors, which can disrupt operations and impact customer service.

- Seasonality: Businesses with seasonal demand patterns may face challenges in managing inventory levels effectively throughout the year.

Summary of the Goal of Inventory Management

In essence, the goal of inventory management is to maintain the right amount of inventory at the right time and at the right cost. By achieving this goal, businesses can optimize their supply chains, enhance customer service, reduce costs, and improve overall operational efficiency.

Q&A on Inventory Management

Q: What is the primary goal of inventory management?

A: The primary goal of inventory management is to strike a balance between meeting customer demand and minimizing costs.

Q: How does inventory management impact customer satisfaction?

A: Effective inventory management ensures product availability, leading to reduced stockouts and faster order fulfillment, enhancing customer satisfaction.

Q: What are the key objectives of inventory management?

A: The key objectives of inventory management include maintaining optimal stock levels, minimizing carrying costs, maximizing customer service, improving supply chain efficiency, and reducing waste and obsolescence.

Q: What strategies are used for effective inventory management?

A: Common strategies for effective inventory management include demand forecasting, inventory classification, safety stock management, just-in-time (JIT) inventory, and vendor-managed inventory (VMI).

Q: What are the advantages of inventory management?

A: Advantages of inventory management include improved customer service, reduced costs, enhanced supply chain efficiency, increased sales, and improved decision-making.

Q: What are the disadvantages of inventory management?

A: Disadvantages of inventory management include carrying costs, risk of obsolescence, complexity, potential for errors, and seasonality.

Q: How can businesses optimize inventory levels?

A: Businesses can optimize inventory levels through demand forecasting, inventory classification, and safety stock management.

Q: What is the role of technology in inventory management?

A: Technology plays a crucial role in inventory management, enabling real-time tracking, automated reordering, and data analysis for informed decision-making.

Q: How can businesses reduce inventory costs?

A: Businesses can reduce inventory costs by minimizing carrying costs, optimizing stock levels, and implementing just-in-time (JIT) inventory practices.

Q: What are the key performance indicators (KPIs) for inventory management?

A: Common KPIs for inventory management include inventory turnover, inventory accuracy, stockout rate, and carrying costs.

Q: How does inventory management impact financial performance?

A: Effective inventory management can improve financial performance by reducing carrying costs, preventing losses due to spoilage or obsolescence, and optimizing cash flow.

Q: What are the emerging trends in inventory management?

A: Emerging trends in inventory management include the adoption of artificial intelligence (AI), machine learning (ML), and blockchain technology for enhanced inventory visibility, forecasting, and optimization.

Conclusion

Inventory management is a multifaceted discipline that requires a strategic approach to achieve its objectives of optimizing stock levels, minimizing costs, and enhancing customer service. By implementing effective inventory management practices, businesses can streamline their supply chains, improve operational efficiency, and gain a competitive advantage in the marketplace.

Rebuttal

Some may argue that inventory management is a non-essential function that adds unnecessary costs to businesses. However, this argument overlooks the crucial role that inventory management plays in ensuring product availability, reducing waste, and optimizing supply chain performance. Without effective inventory management, businesses would face significant challenges in meeting customer demand, controlling costs, and achieving profitability.

In today’s dynamic business environment, where customer expectations are constantly evolving and supply chains are becoming increasingly complex, inventory management is more important than ever before. By embracing innovative technologies and adopting best practices, businesses can unlock the full potential of inventory management to drive growth, enhance customer satisfaction, and achieve operational excellence.