Unlocking the Power of Inventory Management: A Comprehensive Guide for Businesses

In the ever-evolving landscape of business operations, efficient inventory management has emerged as a cornerstone for success. It empowers businesses to optimize their supply chains, reduce costs, and enhance customer satisfaction. This comprehensive guide will delve into the intricacies of inventory management systems, exploring their value propositions, key pain points, and the compelling advantages they offer to businesses.

Navigating the Labyrinth of Inventory Management

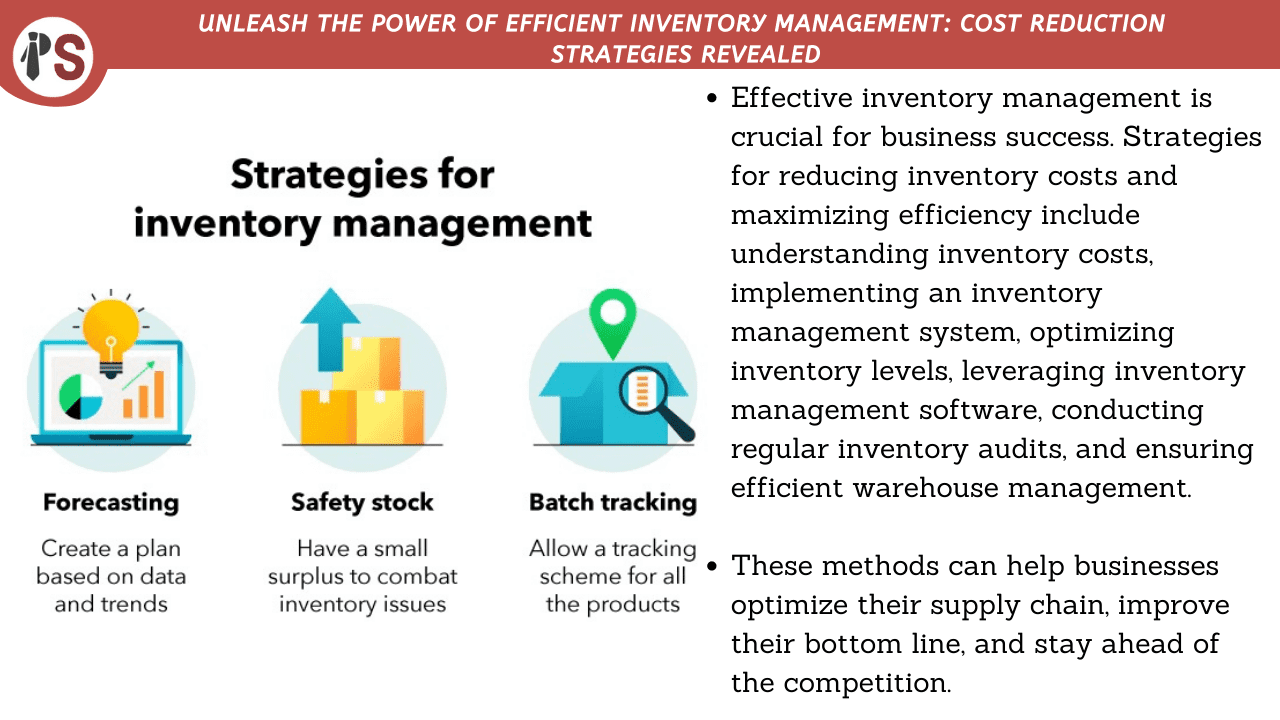

Inventory management encompasses the meticulous planning, organizing, and controlling of a company’s inventory levels. It involves a delicate balance between maintaining adequate stock to meet customer demand and minimizing the risks associated with excess inventory. Effective inventory management systems streamline these processes, enabling businesses to achieve operational excellence.

Unveiling the Value Propositions of Inventory Management Systems

-

Enhanced Visibility and Control: Inventory management systems provide a centralized platform for businesses to monitor and track their inventory levels in real-time. This enhanced visibility empowers decision-makers with up-to-date information, enabling them to make informed decisions regarding inventory replenishment and allocation.

-

Optimized Stock Levels: By leveraging sophisticated algorithms and forecasting techniques, inventory management systems determine optimal stock levels for each item, taking into account factors such as demand patterns, lead times, and safety stock requirements. This optimization minimizes the risks of overstocking and understocking, ensuring that businesses can meet customer demand without incurring excessive inventory costs.

-

Reduced Costs: Inventory management systems automate many inventory-related tasks, such as order processing, inventory counting, and stock replenishment. This automation reduces the need for manual labor, leading to significant cost savings. Additionally, by optimizing stock levels, businesses can minimize carrying costs, storage costs, and the risk of inventory obsolescence.

-

Improved Customer Service: Efficient inventory management ensures that businesses can fulfill customer orders accurately and promptly. By maintaining optimal stock levels, businesses can reduce the likelihood of stockouts, backorders, and delayed deliveries, enhancing customer satisfaction and loyalty.

-

Increased Sales and Revenue: By optimizing inventory levels and improving customer service, inventory management systems can contribute to increased sales and revenue. Businesses can capture more sales opportunities by ensuring that they have the right products in stock at the right time.

Addressing the Key Pain Points of Ideal Customer Personas

-

Inefficient Inventory Management Processes: Manual inventory management processes are prone to errors, delays, and inconsistencies. This inefficiency can lead to stockouts, overstocking, and inaccurate inventory records, hindering business operations and customer satisfaction.

-

Lack of Real-Time Visibility: Without a centralized inventory management system, businesses may struggle to obtain real-time visibility into their inventory levels. This lack of visibility makes it difficult to make informed decisions regarding inventory replenishment and allocation, leading to potential stockouts or excess inventory.

-

High Inventory Costs: Ineffective inventory management can result in excessive inventory carrying costs, storage costs, and the risk of inventory obsolescence. These costs can significantly impact a business’s profitability and cash flow.

-

Poor Customer Service: Inefficient inventory management can lead to stockouts, backorders, and delayed deliveries, negatively impacting customer satisfaction and loyalty. This can damage a business’s reputation and lead to lost sales.

Embracing the Advantages of Inventory Management Systems

-

Enhanced Accuracy and Efficiency: Inventory management systems automate many inventory-related tasks, reducing the risk of human error and increasing overall efficiency. This automation streamlines inventory management processes, saving time and resources.

-

Real-Time Visibility and Control: Inventory management systems provide a centralized platform for businesses to monitor and track their inventory levels in real-time. This enhanced visibility empowers decision-makers with up-to-date information, enabling them to make informed decisions regarding inventory replenishment and allocation.

-

Optimized Inventory Levels: Inventory management systems leverage sophisticated algorithms and forecasting techniques to determine optimal stock levels for each item, taking into account factors such as demand patterns, lead times, and safety stock requirements. This optimization minimizes the risks of overstocking and understocking, ensuring that businesses can meet customer demand without incurring excessive inventory costs.

-

Reduced Costs: Inventory management systems automate many inventory-related tasks, such as order processing, inventory counting, and stock replenishment. This automation reduces the need for manual labor, leading to significant cost savings. Additionally, by optimizing stock levels, businesses can minimize carrying costs, storage costs, and the risk of inventory obsolescence.

-

Improved Customer Service: Efficient inventory management ensures that businesses can fulfill customer orders accurately and promptly. By maintaining optimal stock levels, businesses can reduce the likelihood of stockouts, backorders, and delayed deliveries, enhancing customer satisfaction and loyalty.

-

Increased Sales and Revenue: By optimizing inventory levels and improving customer service, inventory management systems can contribute to increased sales and revenue. Businesses can capture more sales opportunities by ensuring that they have the right products in stock at the right time.

Weighing the Pros and Cons of Inventory Management Systems

Advantages:

-

Enhanced accuracy and efficiency: Inventory management systems automate many inventory-related tasks, reducing the risk of human error and increasing overall efficiency. This automation streamlines inventory management processes, saving time and resources.

-

Real-time visibility and control: Inventory management systems provide a centralized platform for businesses to monitor and track their inventory levels in real-time. This enhanced visibility empowers decision-makers with up-to-date information, enabling them to make informed decisions regarding inventory replenishment and allocation.

-

Optimized inventory levels: Inventory management systems leverage sophisticated algorithms and forecasting techniques to determine optimal stock levels for each item, taking into account factors such as demand patterns, lead times, and safety stock requirements. This optimization minimizes the risks of overstocking and understocking, ensuring that businesses can meet customer demand without incurring excessive inventory costs.

-

Reduced costs: Inventory management systems automate many inventory-related tasks, such as order processing, inventory counting, and stock replenishment. This automation reduces the need for manual labor, leading to significant cost savings. Additionally, by optimizing stock levels, businesses can minimize carrying costs, storage costs, and the risk of inventory obsolescence.

-

Improved customer service: Efficient inventory management ensures that businesses can fulfill customer orders accurately and promptly. By maintaining optimal stock levels, businesses can reduce the likelihood of stockouts, backorders, and delayed deliveries, enhancing customer satisfaction and loyalty.

-

Increased sales and revenue: By optimizing inventory levels and improving customer service, inventory management systems can contribute to increased sales and revenue. Businesses can capture more sales opportunities by ensuring that they have the right products in stock at the right time.

Disadvantages:

-

Implementation costs: Implementing an inventory management system can involve significant upfront costs, including software licensing fees, hardware costs, and implementation services. These costs can be a barrier for small businesses or businesses with limited budgets.

-

Complexity: Inventory management systems can be complex to implement and manage, especially for businesses with large or complex inventory operations. This complexity may require businesses to invest in training and support to ensure effective implementation and utilization.

-

Data accuracy: The accuracy of an inventory management system is heavily dependent on the accuracy of the data entered into the system. If the data is inaccurate or incomplete, the system may provide misleading information and lead to poor inventory management decisions.

Summary of Inventory Management Systems

Inventory management systems are powerful tools that can help businesses optimize their inventory levels, reduce costs, and improve customer service. These systems provide real-time visibility into inventory levels, automate inventory-related tasks, and leverage sophisticated algorithms to determine optimal stock levels. By implementing an inventory management system, businesses can streamline their inventory management processes, minimize the risks of overstocking and understocking, and enhance their overall operational efficiency.

Frequently Asked Questions

Q1. What are the key benefits of using an inventory management system?

A1. Inventory management systems offer numerous benefits, including enhanced accuracy and efficiency, real-time visibility and control, optimized inventory levels, reduced costs, improved customer service, and increased sales and revenue.

Q2. What are the challenges associated with implementing an inventory management system?

A2. Implementing an inventory management system can involve significant upfront costs, complexity, and the need for accurate data entry.

Q3. How can businesses ensure the accuracy of their inventory management system?

A3. Businesses can ensure the accuracy of their inventory management system by implementing rigorous data entry procedures, conducting regular inventory audits, and utilizing data validation techniques.

Q4. What are the different types of inventory management systems available?

A4. There are various types of inventory management systems available, including perpetual inventory systems, periodic inventory systems, just-in-time inventory systems, and vendor-managed inventory systems.

Q5. How can businesses choose the right inventory management system for their needs?

A5. Businesses should consider factors such as the size and complexity of their inventory operations, their budget, and their specific business requirements when choosing an inventory management system.

Q6. What are the best practices for inventory management?

A6. Best practices for inventory management include maintaining optimal stock levels, implementing safety stock policies, conducting regular inventory audits, and utilizing inventory management software.

Q7. How can businesses measure the effectiveness of their inventory management system?

A7. Businesses can measure the effectiveness of their inventory management system by tracking key metrics such as inventory turnover, inventory accuracy, and customer service levels.

Q8. What are the emerging trends in inventory management?

A8. Emerging trends in inventory management include the adoption of cloud-based inventory management systems, the use of artificial intelligence and machine learning for inventory optimization, and the integration of inventory management systems with other business systems.

Q9. How can businesses leverage inventory management systems to gain a competitive advantage?

A9. Businesses can leverage inventory management